Itekhnoloji yomatshini ye-CNC ye-CNC idlala indima ebalulekileyo kwintsimi yokulungiswa kwamalungu.Iinxalenye ze-CNC ze-CNC zokucwangcisa ngokwezifiso zibonelela amashishini ngokuchaneka okuphezulu, ukusebenza kakuhle kunye nokuguquguquka, ukuhlangabezana neemfuno zamashishini ahlukeneyo kumacandelo alungelelanisiweyo.Nangona kunjalo, kukho izinto ezininzi eziphambili ekufuneka ziqwalaselwe ukuqinisekisa umgangatho womatshini wamacandelo, kwaye eli nqaku liza kuphonononga i-8 yezi zinto ngokweenkcukacha.

Imixholo

1. Umzobo woyilo lomatshini

2. Ukukhetha izinto eziphathekayoinxalenye yomatshini

3. Unxibelelwano kunye nolungelelwaniso

4. Ukukhetha izixhobo kumatshini weCNC

5. Ucwangciso lwenkqubokumatshini weCNC

6. Ukulungisa kunye nokubambainxalenye yomatshini

7. Isicwangciso sendlela yesixhobo kumatshini weCNC

8. Uvavanyo kunye nokulawula umgangathoinxalenye yomatshini

1.Uyilo lokuzoba lomatshini

Njengoxwebhu oluphambili lobugcisa, iphepha alinikezeli kuphela ubungakanani bejometri kunye nolwazi lwemilo yamacandelo, kodwa lihambisa iteknoloji yokucubungula, iimfuno zomgangatho kunye neenjongo zokuyila.Ngoko ke, umzobo ochanekileyo kunye neenkcukacha zoyilo sisiseko sokuqinisekisa umgangatho we-CNC machined parts.Kwinqanaba lokuyila, imizobo yamacandelo kufuneka yenziwe ngokusekelwe kwiimpawu zobuchwepheshe be-CNC.Oku kubandakanya uhlalutyo olubanzi lwenkqubo yomatshini, ukufumana ulwazi lobugcisa bokucutshungulwa kweenxalenye, ezifana nesixa sokusika, indlela yomatshini kunye nesixhobo sokuhamba kwesixhobo, njl. njl., kunye nokurekhoda ulwazi lwe-machining olusekelwe kwimeko yokwenyani yokubonelela ngesiseko sedatha ye-machining yangempela. umsebenzi.

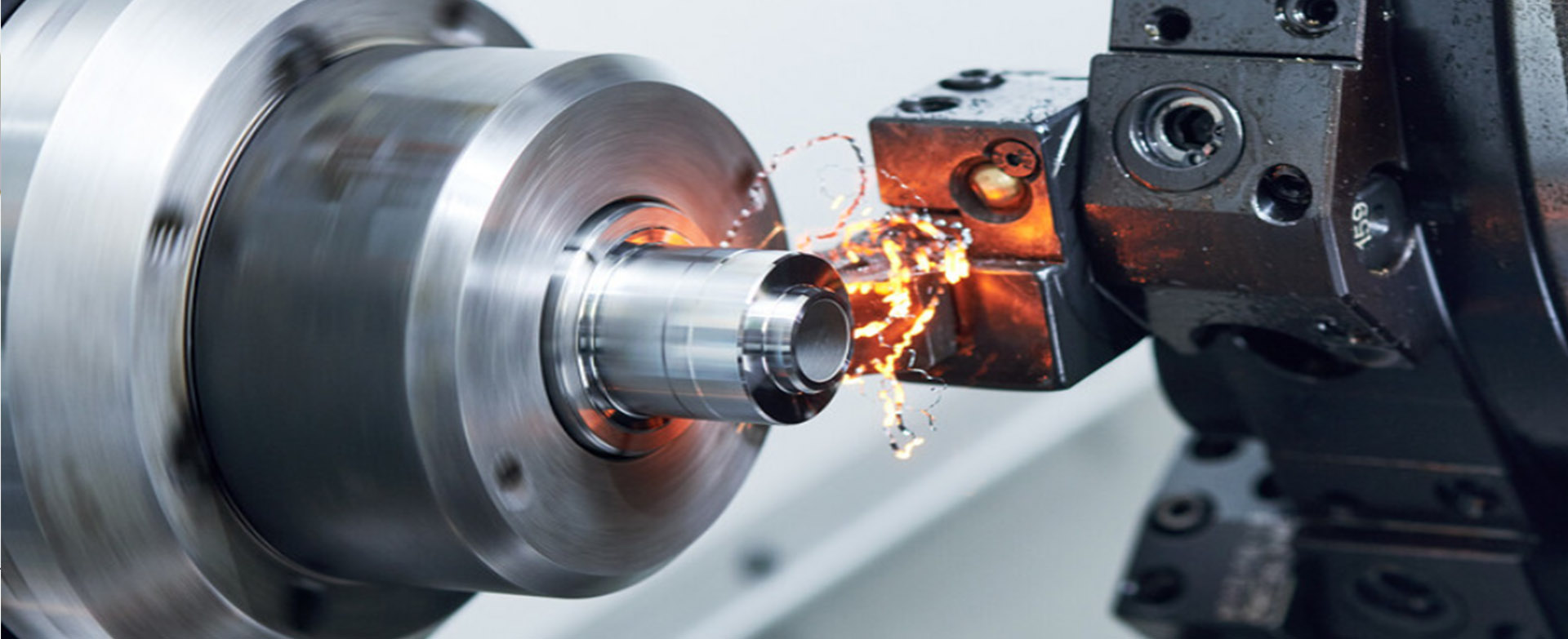

2. Ukukhethwa kwezinto eziphathekayo kwi-part machining

Ukukhethwa kwezinto eziphathekayo nakho kuyinkalo ebalulekileyo, njengoko iimpawu ezibonakalayo kunye neekhemikhali ze-CNC zokwenziwa ngomatshini ziya kuchaphazela ubugcisa, iindleko kunye nomgangatho opheleleyo wecandelo eligqityiweyo.Ngokomzekelo, iimveliso zetsimbi, ngenxa yokuqina kwazo kwaye zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala khona.Xa ukuguqula okanye ukugaya izinyithi ezinzima ezifana nentsimbi ephezulu, i-titanium alloy, insimbi engenasici, njl., ukuxhatshazwa kwesixhobo kufuneka kube phezulu.Ukusetyenzwa kwezixhobo kuchaphazela ngqo ukusebenza kakuhle kunye nomgangatho.Izinto ekulula ukuziqhuba zinokunyusa ukusebenza kakuhle kwemveliso.Ngelo xesha, i-geometry yamacandelo aza kucutshungulwa, imeko yezinto eziphathekayo, ukulungiswa kunye nokuqina kwezixhobo zokusika ezisetyenziswe kwisixhobo somatshini nazo zibalulekile ekukhethweni kwezixhobo zokusika i-CNC.

3. Unxibelelwano kunye nolungelelwaniso

Unxibelelwano kunye nokulungelelaniswa akunakungahoywa kwi-CNC parts processing.Inkqubo yokucubungula ibandakanya izixhumanisi ezininzi, kubandakanywa ukuyila, ukuqhutyelwa phambili, ukulawula umgangatho, njl., kufuna intsebenziswano esondeleyo kunye nokutshintshiselana ngolwazi phakathi kwamaqela ahlukeneyo.Unxibelelwano olucacileyo kunye nolungelelwaniso luqinisekisa ukuba iimfuno zokucubungula, iinkqubo kunye nemigangatho yomgangatho iyahambelana kuzo zonke ikhonkco.Unxibelelwano oluthe rhoqo lunceda ukuphepha ukungaqondi kakuhle kolwazi.Ukongeza, unxibelelwano lwangexesha lunokunceda ukulungelelanisa ngokukhawuleza izicwangciso zokucwangcisa ezingafanelekanga kunye neenkqubo zokujongana nemingcipheko enokwenzeka yokucubungula, ukuqinisekisa inkqubela phambili egudileyo yenkqubo yokucubungula iinxalenye ze-CNC, ukuphucula ukusebenza kakuhle kwemveliso, ukonga ixesha, kunye nokuqinisekisa ukuba umgangatho wemveliso uyahlangabezana nemigangatho.

4. Ukukhethwa kwezixhobo zeCNC machining

Kwakhona kubaluleke kakhulu ukukhetha isixhobo esifanelekileyo somatshini we-CNC ngokwezinto eziphathekayo, i-contour shape, ukuchaneka kokucubungula, njl njl.Izixhobo ezifanelekileyo zinokuqinisekisa ukuzinza kwenkqubo yokucubungula kunye nokunciphisa izinga eliphosakeleyo kunye nesantya se-scrap.Ukongeza, ukukhetha izixhobo eziphambili kunokuphucula ukusebenza kakuhle kwemveliso kunye nokunciphisa umjikelo wokulungisa.Ke ngoko, ngokusekwe kwiimpawu kunye neemfuno zokusetyenzwa kwenxalenye, ukhetho oluchanekileyo lwezixhobo lukwayenye yamanyathelo aphambili okuqinisekisa impumelelo yecandelo le-CNC.

5. Ucwangciso lwenkqubo yokwenziwa komatshini we-CNC

Uyilo lwenkqubo yomatshini ye-CNC kufuneka lugqitywe phambi kokucwangciswa.Umgangatho woyilo uya kuchaphazela ngokuthe ngqo ukusebenza kakuhle kwesixhobo somatshini kunye nomgangatho wokucutshungulwa kwamacandelo acutshungulweyo.Ukukhetha okunengqiqo kwexabiso lokusika kunokunika umdlalo opheleleyo ekusebenzeni kokusika kwesixhobo, ukwandise iiparamitha zenkqubo yomatshini we-CNC, uqinisekise umatshini okhawulezayo we-spindle, ukunciphisa ixesha le-CT lokucutshungulwa kwenxalenye, kwaye ekugqibeleni uphucule ukusebenza kakuhle kwemveliso. kunye nokuphucula umgangatho wemveliso.Ukongezelela, ngokucwangcisa ngokufanelekileyo ulandelelwano lwenkqubo yokucubungula kunye nokunciphisa inani leenguqu zesixhobo, ixesha le-CT processing CNC linokuthi lifinyezwe ngokufanelekileyo kwaye imveliso yanda.

6. Ukulungisa kunye nokubamba inxalenye machining

Ukukhetha indlela efanelekileyo yokudibanisa kunokuphucula umgangatho wokucubungula kunye nokusebenza kakuhle kunye nokunciphisa iindleko zemveliso.Oku kubandakanya ukukhetha indlela efanelekileyo yokudibanisa, ukunikela ingqalelo kuyilo kunye nokuveliswa kwe-clamp, kunye nokulungelelanisa ngokufanelekileyo amandla okubamba.Ukongeza, ngoncedo lwezixhobo zesoftware zanamhlanje, ezinje ngenkqubo ye-UG, sinokwenza i-clamping ebonakalayo kunye nohlalutyo lokulungisa ukumisela eyona ndlela ilungileyo yokulungisa.Ngokufanisa inkqubo yomatshini, sinokubona ukuguqulwa kunye nokufuduka kwe-workpiece ngexesha lenkqubo yokucoca, kunye nokulungelelanisa indlela yokulungisa ngokweziphumo zokulinganisa ukufezekisa umphumo ongcono wokwenza.

7. Isicwangciso sendlela yesixhobo somatshini we-CNC

Indlela yesixhobo ibhekiselele kwindlela yokuhamba kunye nolwalathiso lwesixhobo esinxulumene nomsebenzi ngexesha lomatshini olawulwayo.Ukukhethwa okufanelekileyo kweendlela zokucubungula kuhambelana ngokusondeleyo nokuchaneka kokulungiswa kunye nomgangatho ophezulu wamacandelo.Ngoko ke, kuyimfuneko ukuqinisekisa iimfuno zokuchaneka komatshini weengxenye, ngelixa uququzelela ukubala kwamanani kunye nokunciphisa ixesha lokucwangcisa.Ukucwangciswa kwendlela kwi-five-axis CNC machining, ibandakanya iinkalo ezimbini: i-trajectory yendawo yoqhagamshelwano yesixhobo (indawo yeziko lesixhobo) (i-3D) kunye ne-posture yesixhobo (2D).Xa uyila indlela yesixhobo, kuthenjwa ukuba indlela yokugqibela iya kuba mfutshane kwaye igudileyo ukufezekisa ukusebenza kakuhle okuphezulu kunye nomgangatho wokuqhuba.

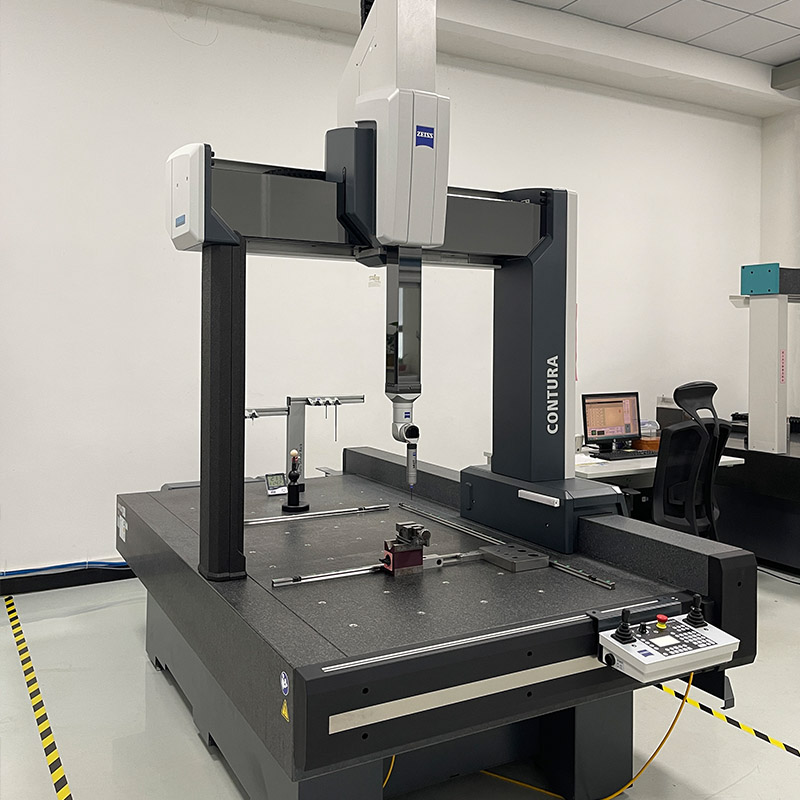

8. Uvavanyo kunye nolawulo lomgangatho wenxalenye machining

Ulawulo lomgangatho ngumba obalulekileyo wenkqubo yokwenziwa kwe-CNC, esebenza kwiinjongo eziphambili ezininzi, kubandakanywa nokuqinisekisa ukuba imveliso yokugqibela idibana nemigangatho efunekayo kunye neenkcukacha.Ngokusebenzisa izixhobo zokulinganisa eziphucukileyo kunye neendlela, sinokubeka iliso kwinkqubo yomatshini ngexesha langempela, sifumanise kwaye silungise iingxaki ngexesha elifanelekileyo ukuze siqinisekise ukuba umgangatho wamacandelo udibana nemigangatho elindelekileyo kunye neenkcukacha.

Ubunakho boMatshini beGPM:

I-GPM ineminyaka engama-20 yamava kwi-CNC machining yeentlobo ezahlukeneyo zamalungu achanekileyo.Sisebenze kunye nabathengi kumashishini amaninzi, kubandakanywa i-semiconductor, izixhobo zonyango, njl.Samkela inkqubo engqongqo yolawulo lomgangatho ukuqinisekisa ukuba inxalenye nganye iyahlangabezana nokulindelwe ngabathengi kunye nemigangatho.

Ixesha lokuposa: Dec-21-2023