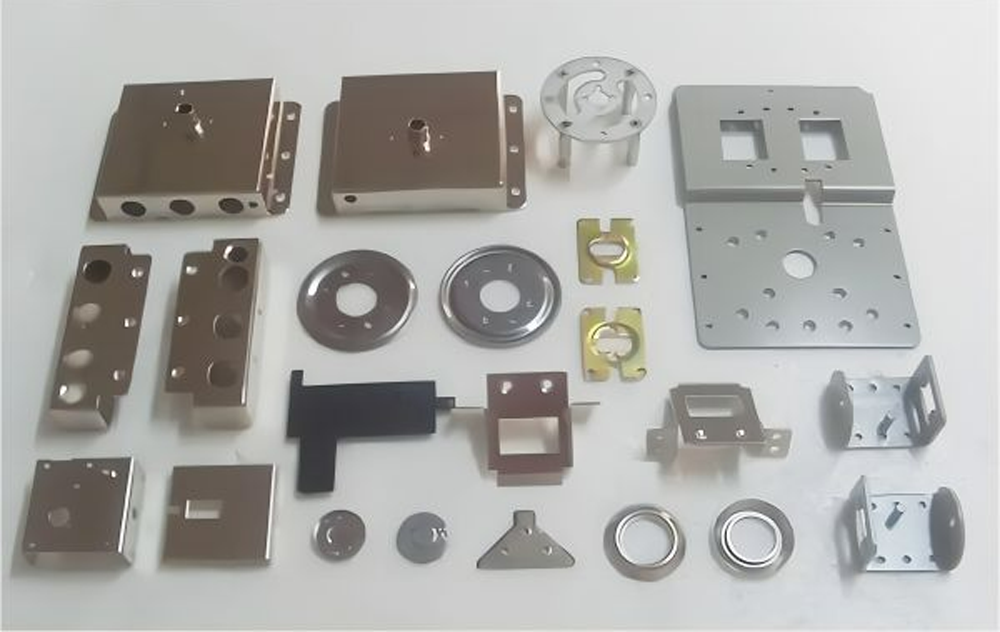

Habaynta biraha xaashida waa nooc ka mid ah tignoolajiyada farsamaynta marka loo eego xaashida birta, oo ay ku jiraan foorarsiga, feedhitaanka, kala bixinta, alxanka, kabidda, samaynta, iwmOo waxay leedahay sifooyinka miisaanka fudud, saxnaanta sare, qallafsanaanta wanaagsan, qaab-dhismeedka dabacsan iyo muuqaalka quruxda badan.GPM waxa ay bixisaa adeegyo habaynta birta waxayna leedahay koox khibrad iyo xirfad leh oo ku siin kara adeegyo hal-joojin ah laga bilaabo hagaajinta naqshadaynta DFM, wax-soo-saarka ilaa isu-ururinta.Alaabooyinku waxay daboolayaan noocyada kala duwan ee chassis, armaajooyinka, sanduuqyada, racks-yada, iwm.

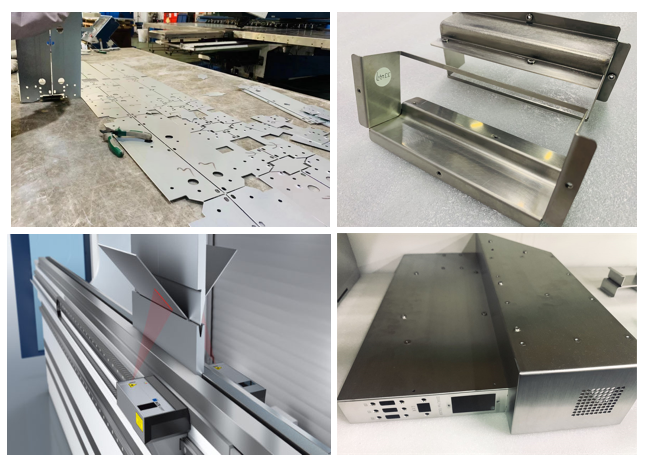

Goynta Laser-ka

Shaabadeynta

foorarsan

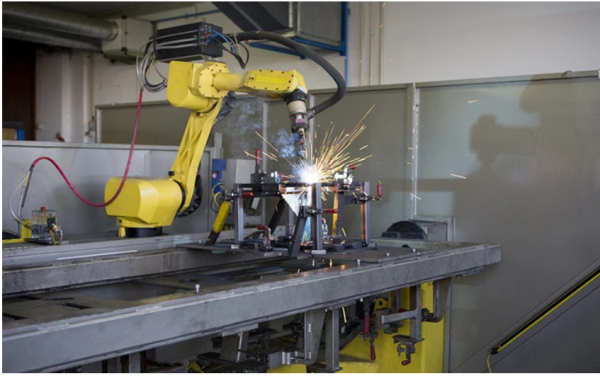

alxanka

Mashiinka farsamaynta

Farsamaynta farsamaynta ee biraha xaashida ah inta lagu jiro wax soo saarka waxay la xiriirtaa tayada alaabta.Sababtan awgeed, waxaa lagama maarmaan ah in la isticmaalo qalabka wax lagu farsameeyo ee casriga ah iyo tignoolajiyada horumarsan si loo dhamaystiro hawlaha kala duwan ee tignoolajiyada si habsami leh.Waxaad heli doontaa alaab tayo sare leh iyo khibrad adeeg oo tayo sare leh, adoo dooranaya adeegyadayada habaynta birta,

| Magaca mashiinka | QTY (la dhigay) |

| Mashiinka Goynta Laser Power Sare | 3 |

| Mashiinka wax-ka-saarka tooska ah | 2 |

| Mashiinka foorarsiga ee CNC | 7 |

| Mashiinka dhogorta ee CNC | 1 |

| Mashiinka alxanka Argon | 5 |

| alxanka Robot | 2 |

| Mashiinka alxanka tollayn toosan oo toos ah | 1 |

| Cadaadiska feerka Hydraulic 250T | 1 |

| Mashiinka quudinta tooska ah | 6 |

| Mashiinka tuubada | 3 |

| Mashiinka qodista | 3 |

| Mashiinka rullaluistemadka | 2 |

| Wadarta | 36 |

Qalabka

Habaynta birta xaashida waxay isticmaali kartaa agabyo kala duwan, kuwaas oo lagu dooran karo iyadoo loo eegayo xaaladaha codsiga iyo shuruudaha.Kuwa soo socda ayaa ah qaar ka mid ah qalabka wax lagu sameeyo ee birta ah ee caadiga ah

Aluminium aluminium

A1050, A1060, A1070, A5052, A7075 iwm.

Bir daxal laheyn

SUS201, SUS304, SUS316, SUS430, iwm.

Birta kartoonka

SPCC, SECC, SGCC, Q35, # 45, iwm.

Daawaha Copper

H59, H62, T2, iwm.

Dhammaysta

Daaweynta dusha sare ee farsamaynta biraha xaashida waxaa lagu dooran karaa iyadoo loo eegayo baahiyaha dhabta ah si loo daboolo baahiyaha xaaladaha kala duwan ee codsiga.

●Duubista:Galvanized, Dahab dahab ah, dahaadhay nikkel, chrome dahaadhay, aluminium zinc nikkel, dahaadhaynta titanium, dahaadhay Ion, iwm.

●Anodized:oksidation adag, anodized cad, anodized midabka, iwm.

●Dahaarka:Daahan hydrophilic, daahan hydrophobic, daahan vacuum, dheeman sida kaarboon (DLC)

●shaandhaynta:Daalida makaanikada, polishing electrolytic, polishing kiimikada iyo nano polishing

Habayn kale oo habaysan iyo dhammays tirsiga codsiga

Codsiyada

Waxaa jira noocyo badan oo hababka wax soo saarka biraha xaashida, oo ay ku jiraan goynta, feeray / goynta / isku xidhka, laalaabida, alxanka, riveting, splicing, samaynta, iwm alaabta biraha xaashida waxaa si ballaaran loo isticmaalaa in warshadaha iyo beeraha kala duwan.Wax-soo-saarka alaabada xaashida ah waa in lagu daraa codsiga alaabta, deegaanka iyo arrimo kale, oo si buuxda u tixgeliya macquulnimada qiimaha, qaabka, xulashada alaabta, qaab-dhismeedka, habka iyo dhinacyada kale.

Alaabooyinka birta ah ee xaashida waxay leeyihiin sifooyinka miisaanka fudud, xoogga sare, dhaqdhaqaaqa wanaagsan, kharash yar iyo waxqabadka wax soo saarka dufcada wanaagsan.Waxaa si weyn loogu isticmaalaa elektiroonigga, isgaarsiinta, warshadaha baabuurta, qalabka caafimaadka iyo qaybaha kale oo ay ku jiraan laakiin aan ku xaddidnayn:

●Xiritaanka koronto

●Chassis

●Gawaarida

●Golaha wasiirada

●Buuraha

●Qalabka

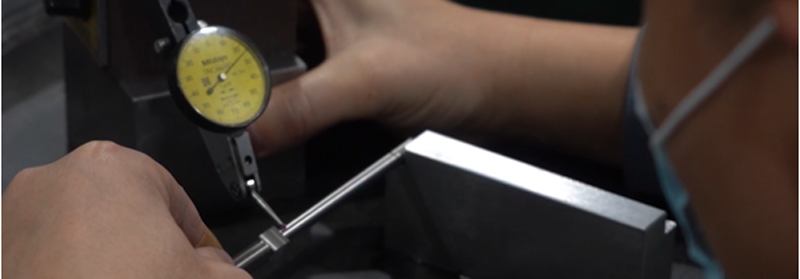

Xaqiijinta Tayada

Xakamaynta tayada waa qayb muhiim ah oo ka mid ah gaaritaanka alaabada habaynta birta saxan oo tayo sare leh.Qaadashada nidaamyada maaraynta tayada kala duwan iyo qalabka tijaabada, GPM waxay hubisaa xasiloonida iyo isku halaynta socodka habka iyo tayada alaabta.Laga soo bilaabo soo iibinta alaabta ceeriin, xakamaynta habka wax-soo-saarka ilaa kormeerka alaabta la dhammeeyey ka dib marka la sameeyo, xakamaynta tayada adag iyo kormeerka ayaa loo baahan yahay.

| Muuqaal | Dulqaad |

| Cidhif ilaa gees, oogada qudha | +/- 0.127 mm |

| Cidhif ilaa dalool, dusha keliya | +/- 0.127 mm |

| Dalool ilaa dalool, oog keliya | +/- 0.127 mm |

| U laabi cidhifka i dalool, hal dusha sare | +/- 0.254 mm |

| Daraf si aad u muujiso, oog badan | +/- 0.254 mm |

| In ka badan qayb la sameeyay, oog badan | +/- 0.762 mm |

| Laabi xagal | +/- 1 darajo |