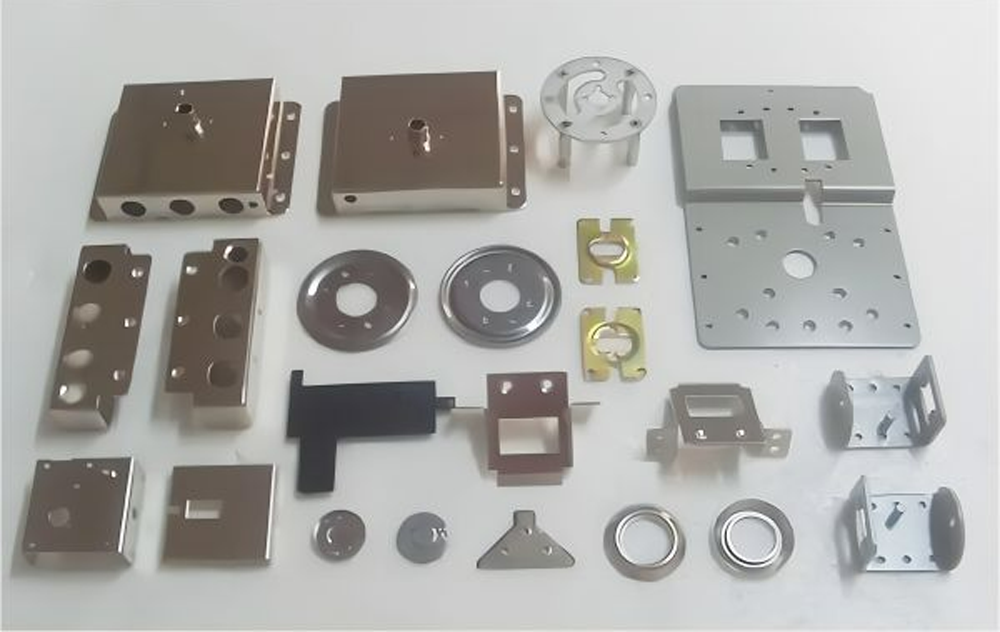

sarrafa karafa nau'i ne na fasaha na sarrafawa dangane da zanen karfe, wanda ya hada da lankwasa, naushi, mikewa, walda, splicing, forming, da dai sauransu. Siffar sa a fili ita ce sassa iri daya suna da kauri iri daya.Kuma yana da halaye na nauyin haske, babban madaidaici, mai kyau rigidity, tsarin sassauƙa da kyakkyawan bayyanar.GPM yana ba da sabis na sarrafa ƙarfe na takarda kuma yana da ƙwararrun ƙwararrun ƙwararrun da za su iya ba ku sabis na tsayawa ɗaya daga haɓaka ƙirar DFM, masana'anta zuwa taro.samfuran suna rufe nau'ikan chassis daban-daban, kabad, kabad, akwatunan nuni, da sauransu, kuma ana amfani da su sosai a cikin kayan lantarki, sadarwa, likitanci, binciken kimiyya da sauran fannoni.

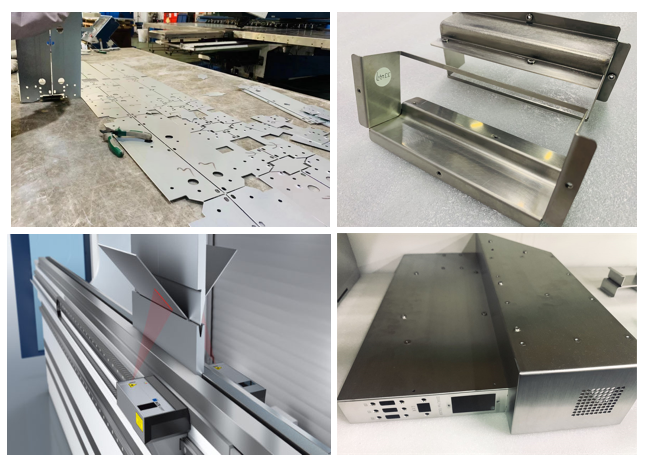

Laser Yankan

Tambari

Lankwasawa

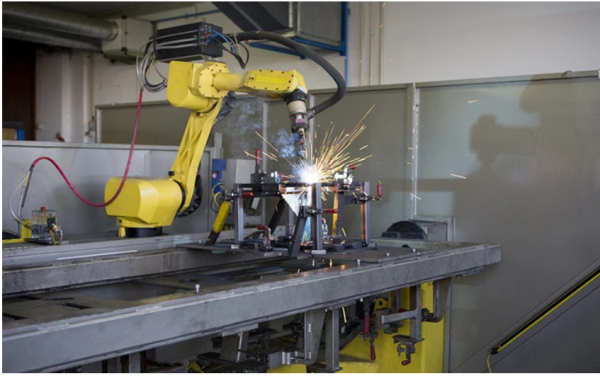

Walda

Injin sarrafawa

Fasahar sarrafa takarda a lokacin masana'anta yana da alaƙa da ingancin samfur.Don haka, ya zama dole a yi amfani da na'urori na zamani na zamani da na'urorin zamani don kammala ayyukan fasaha daban-daban cikin tsari.Za ka samu high quality-kayayyakin da high quality-sabis gwaninta, da zabar mu sheet karfe aiki ayyuka,

| Sunan inji | QTY (saitin) |

| High Power Laser Yankan Machine | 3 |

| Injin cirewa ta atomatik | 2 |

| CNC lankwasawa inji | 7 |

| CNC Shearing Machine | 1 |

| Argon walda inji | 5 |

| Robot walda | 2 |

| Madaidaicin kabu waldi inji | 1 |

| Na'ura mai aiki da karfin ruwa Punch Press 250T | 1 |

| Injin rivet ciyarwa ta atomatik | 6 |

| Injin bugawa | 3 |

| Injin latsawa | 3 |

| Na'ura mai juyi | 2 |

| Jimlar | 36 |

Kayayyaki

Tsarin ƙarfe na takarda na iya amfani da abubuwa iri-iri, waɗanda za a iya zaɓa bisa ga yanayin aikace-aikacen da buƙatu.Wadannan su ne wasu kayan sarrafa ƙarfe na gama gari

Aluminum gami

A1050, A1060, A1070, A5052, A7075 da dai sauransu.

Bakin karfe

SUS201, SUS304, SUS316, SUS430, da dai sauransu.

Karfe Karfe

SPCC, SECC, SGCC, Q35, #45, da dai sauransu.

Copper gami

H59, H62, T2, da dai sauransu.

Ya ƙare

Za'a iya zaɓin jiyya na kayan aiki na takarda bisa ga ainihin bukatun don saduwa da bukatun yanayi daban-daban na aikace-aikacen.

●Plating:Galvanized, plating na zinariya, plating nickel, chrome plating, tutiya nickel gami, titanium plating, ion plating, da dai sauransu.

●Anodized:Hard hadawan abu da iskar shaka, bayyanannun anodized, launi anodized, da dai sauransu.

●Tufafi:Hydrophilic shafi, hydrophobic shafi, injin shafi, lu'u-lu'u kamar carbon (DLC) , PVD (zinariya TiN, baki: TiC, azurfa: CrN)

●goge baki:Gyaran injina, gogewar lantarki, gogewar sinadarai da gogewar nano

Sauran sarrafa al'ada da ƙare akan buƙata.

Aikace-aikace

Akwai da yawa irin sheet karfe samar matakai, ciki har da yankan, punching / yankan / compounding, nadawa, waldi, riveting, splicing, forming, da dai sauransu Sheet karfe kayayyakin da ake amfani da ko'ina a daban-daban masana'antu da filayen.Ya kamata a haɗu da masana'anta na samfuran ƙarfe tare da aikace-aikacen samfur, yanayi da sauran dalilai, kuma cikakken la'akari da ma'anar farashi, siffar, zaɓin kayan, tsari, tsari da sauran fannoni.

Samfuran ƙarfe na takarda suna da halaye na nauyin haske, ƙarfin ƙarfi, haɓaka mai kyau, ƙarancin farashi da kyakkyawan aikin samar da tsari.Ana amfani da shi sosai a cikin kayan lantarki, sadarwa, masana'antar kera motoci, kayan aikin likita da sauran fannoni ciki har da amma ba'a iyakance ga:

●Wurin lantarki

●Chassis

●Brackets

●Majalisar ministoci

●Tsaunuka

●Kayan aiki

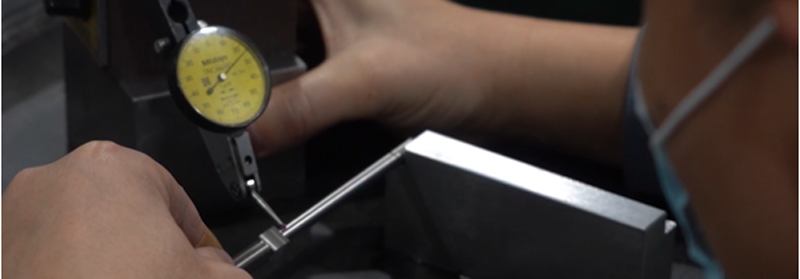

Tabbacin inganci

Kula da inganci wani muhimmin sashi ne na samun ingantattun samfuran sarrafa kayan ƙarfe masu inganci.Ta hanyar ɗaukar tsarin gudanarwa iri-iri da kayan gwaji, GPM yana tabbatar da kwanciyar hankali da amincin tsarin tafiyar da ingancin samfur.Daga siyan kayan albarkatun kasa, sarrafa tsarin sarrafawa zuwa duba samfuran da aka gama bayan sarrafawa, ana buƙatar ingantaccen kulawa da kulawa.

| Siffar | Hakuri |

| Gefe zuwa gefe, saman ƙasa ɗaya | +/- 0.127 mm |

| Gefe zuwa rami, saman ƙasa ɗaya | +/- 0.127 mm |

| Ramin zuwa rami, fage guda ɗaya | +/- 0.127 mm |

| Lanƙwasa zuwa gefen i rami, guda ɗaya | +/- 0.254 mm |

| Gefen zuwa fasali, saman da yawa | +/- 0.254 mm |

| Sama da ɓangarorin da aka kafa, saman da yawa | +/- 0.762 mm |

| Lanƙwasa kwana | +/- 1 digiri |