Adeegga Mashiinka ee CNC

GPM waa bixiyaha adeegga mashiinada saxda ah.Waxaan haysanaa qalab farsamaysan oo horumarsan iyo injineero xirfad leh si aan macaamiisha u siino adeegyo farsamayn oo tayo sare leh.Ma jiro wax-soo-saarka mitirka ama wax-soo-saarka buuxa, waxaan ku siin karnaa adeegyada habsocodka oo ay ku jiraan habab farsamo oo kala duwan sida wax-shiididda, leexinta, qodista, iyo shiididda si loo daboolo baahiyaha kala duwan ee macaamiisha.Waxaan fiiro gaar ah u siineynaa tayada iyo hufnaanta, waxaanan dammaanad qaadeynaa inaan macaamiisha siino alaab iyo adeegyo tayo sare leh waqtiga ugu yar ee suurtogalka ah.

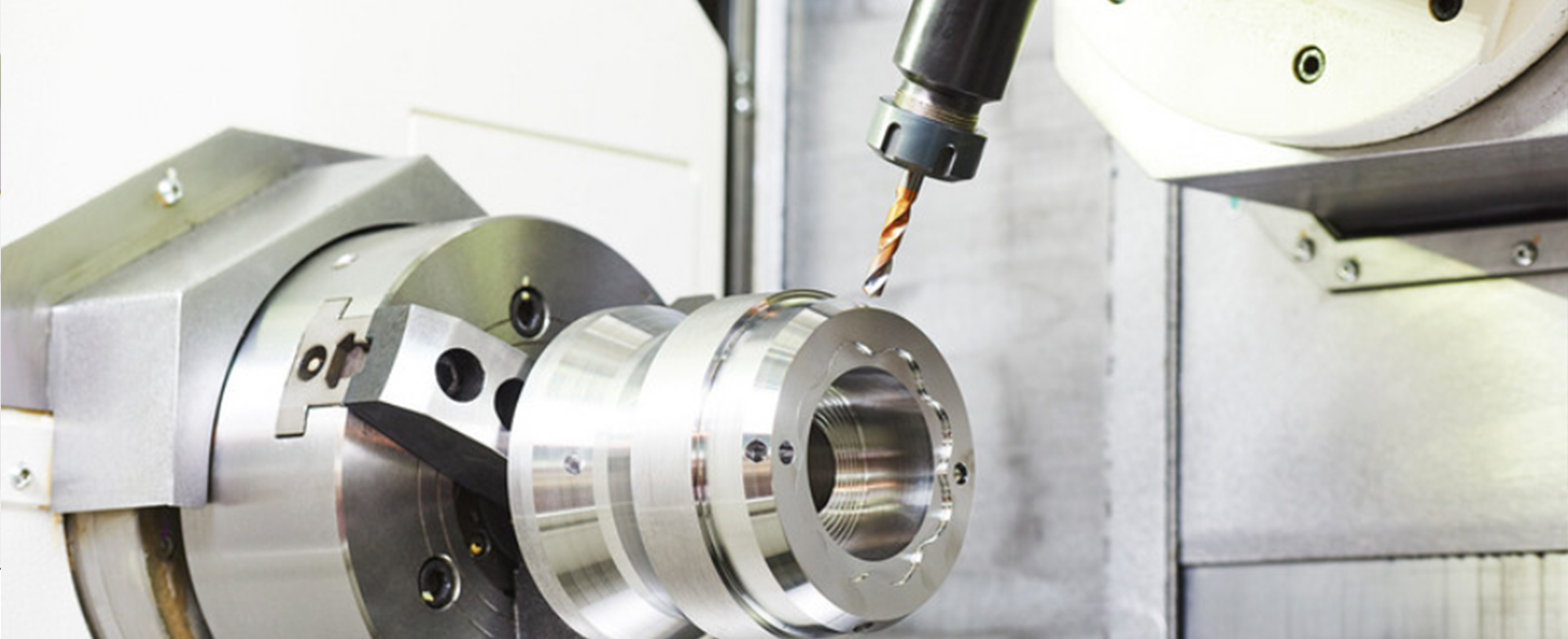

CNC Milling

3-dhidib, 4-dhidib, 5-dhidib machining

Shididada CNC waxay kaa caawin kartaa inaad gaarto saxnaanta sare, hufnaanta sare iyo farsamaynta soo noqnoqda, waxayna xamili kartaa qaabab kala duwan oo adag, shaqo-yaqaanno waaweyn iyo kuwo yar yar si loo yareeyo hawlaha gacanta, hagaajinta tayada wax soo saarka iyo tayada, hoos u dhigista wareegyada wax soo saarka iyo kharashka wax soo saarka.

| Magaca mashiinka | Summada | Meesha Asal ahaan | Dhimashada ugu badan ee mashiinka (mm) | Tirada | Saxnimada (mm) |

| Shan-Axis | Okuma | Japan | 400X400X350 | 8 | ± 0.003-0.005 |

| Xawaaraha Sare ee Shan-Axis | Jing Diao | Shiinaha | 500X280X300 | 1 | ± 0.003-0.005 |

| Afar dhidib Horizontal | Okuma | Japan | 400X400X350 | 2 | ± 0.003-0.005 |

| Afar dhidib oo toosan | Mazak/Walaal | Japan | 400X250X250 | 32 | ± 0.003-0.005 |

| Gantry Machining | Taikan | Shiinaha | 3200X1800X850 | 6 | ± 0.003-0.005 |

| Mashiinka Qodista Xawaaraha Sare | Walaal | Japan | 3200X1800X850 | 33 | - |

| Saddex dhidib | Mazak/Prefect-Jet | Japan/Shiinaha | 1000X500X500 | 48 | ± 0.003-0.005 |

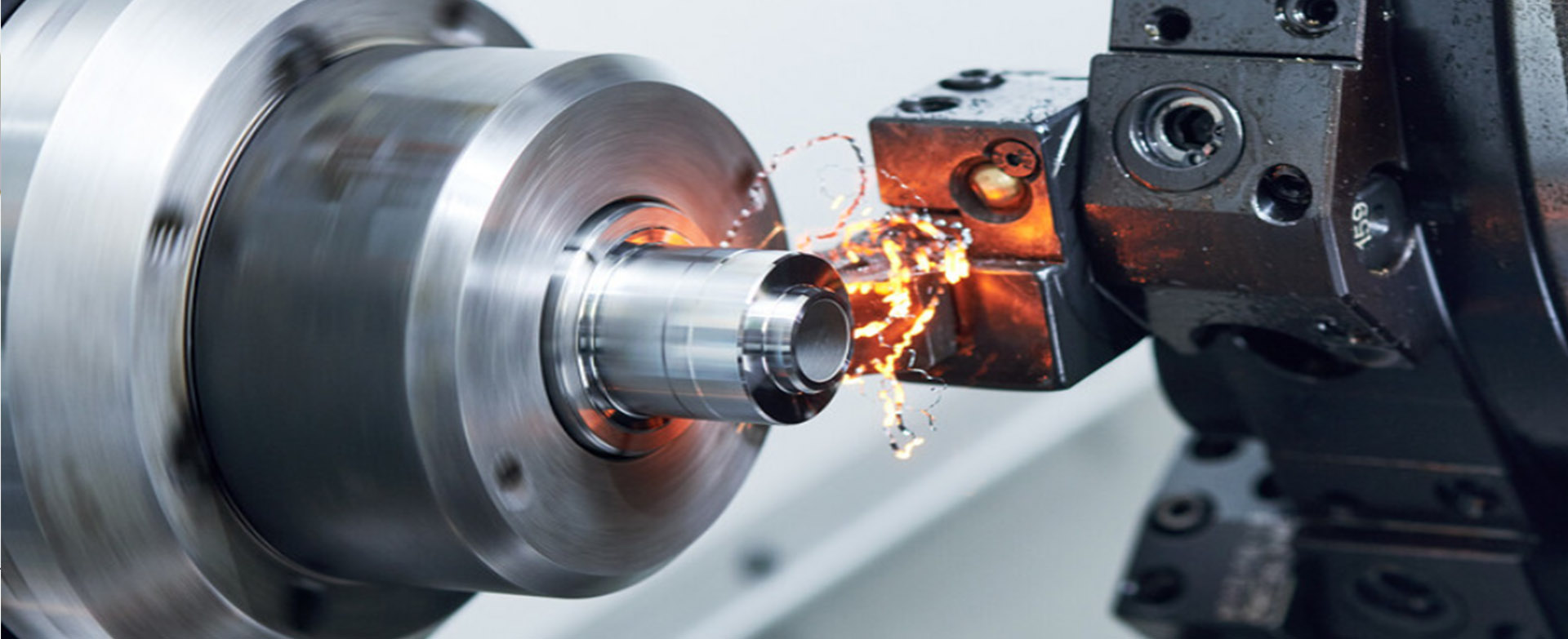

Jeedinta CNC

Lathe CNC, socodka xudunta u ah, mishiinka gooya

CNC leexashada waxaa si weyn loogu isticmaalaa in processing of workpieces beeraha baabuurta, mishiinada, duulista iyo hawada.Warshadaha wax soo saarka ee kala duwan, CNC Turning waa mid ka mid ah tignoolajiyada muhiimka ah si ay kaaga caawiyaan inaad ku guulaysato mugga sare, farsamaynta saxda ah ee saxda ah.

| Nooca Mashiinka | Magaca mashiinka | Summada | Meesha Asal ahaan | Dhimashada ugu badan ee Machining (mm) | Tirada | Saxnimada (mm) |

| Jeedinta CNC | Socodka Muhiimka ah | Muwaadin/Xiddig | Japan | Ø25X205 | 8 | ± 0.002-0.005 |

| Mindi Quudiye | Miyano/Takisawa | Japan/Taiwan, Shiinaha | Ø108X200 | 8 | ± 0.002-0.005 | |

| CNC Lathe | Okuma/Tsugami | Japan/Taiwan, Shiinaha | Ø350X600 | 35 | ± 0.002-0.005 | |

| Lath Toosan | Wanaagsan | Taiwan, Shiinaha | Ø780X550 | 1 | ± 0.003-0.005 |

Shiididda & Xadhka Goynta

Hagaajinta saxnaanta mashiinka iyo tayada

Tiknoolajiyada kaalmaynta mashiinnada saxda ah, sida shiididda iyo goynta siliga, waxay ku siin kartaa aalado sax ah oo sax ah iyo habab, kuwaas oo xakameyn kara khaladaadka inta lagu jiro habka farsamaynta, taas oo hagaajinaysa saxnaanta mashiinnada iyo tayada qaybaha iyada oo loo marayo habab wax-qabad oo kala duwan iyo teknoolajiyada.Waxay ka baaraandegi kartaa qaybo qaabab iyo qalab kala duwan ah, waxayna sidoo kale ballaarin kartaa awoodda wax-qabadka iyo baaxadda.

| Nooca Mashiinka | Magaca mashiinka | Summada | Meesha Asal ahaan | Dhimashada ugu badan ee Machining (mm) | Tirada | Saxnimada (mm) |

| Shididada CNC | Mashiinka Biyaha Weyn | Kent | Taiwan, Shiinaha | 1000X2000X5000 | 6 | ±0.01-0.03 |

| Shiida Diyaaradda | Seedtec | Japan | 400X150X300 | 22 | ± 0.005-0.02 | |

| Shiidi Gudaha Iyo Dibada | SPS | Shiinaha | Ø200X1000 | 5 | ± 0.005-0.02 | |

| Goynta Siliga Saxda ah | Silig Jogging Sax ah | Agie Charmille | Switzerland | 200X100X100 | 3 | ± 0.003-0.005 |

| EDM-Habab | Sare-Edm | Taiwan, Shiinaha | 400X250X300 | 3 | ± 0.005-0.01 | |

| Goynta Siliga | Sandu/Rijum | Shiinaha | 400X300X300 | 25 | ±0.01-0.02 |

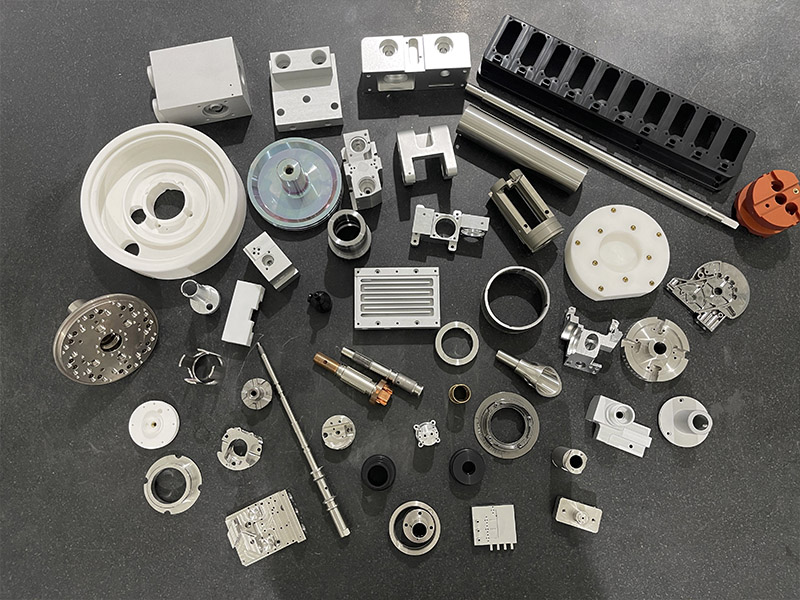

Qalabka

Qalab farsamaynta CNC oo kala duwan

●Aluminium alloy:A6061, A5052, A7075, A2024, A6063 iwm.

●Bir daxal laheyn: SUS303, SUS304, SUS316, SUS316L, SUS420, SUS430, SUS301, iwm.

●Birta kaarboon:20#, 45#, iwm.

●Daawaha naxaasta ah: H59, H62, T2, TU12, Qsn-6-6-3, C17200, iwm.

●Birta tungsten:YG3X, YG6, YG8, YG15, YG20C, YG25C, iwm.

●Walxaha polymer:PVDF, PP, PVC, PTFE, PFA, FEP, ETFE, EFEP, CPT, PCTFE, PEEK, iwm.

●Qalabka isku dhafan:Walxaha isku dhafan ee fiber-carbon, maaddooyinka isku-dhafka ah ee fiber-ka-galaas ah, walxaha isku-dhafka dhoobada ah, iwm.

Dhammaysta

Si dabacsanaan leh ayuu u dhammeeyaa habka codsiga

●Dhigista:Galvanized, Dahab dahab ah, dahaadhay nikkel, chrome dahaadhay, aluminium zinc nikkel, dahaadhaynta titanium, dahaadhay Ion, iwm.

●Anodized: oksaydhation adag, anodized cad, midabka anodized, iwm.

●Dahaarka: Daahan Hydrophilic, daahan hydrophobic, vacuum daahan, dheeman sida kaarboon (DLC), PVD (TiN dahab ah, madow:TiC, silver: CrN).

●Daalid:Daalida makaanikada, polishing electrolytic, polishing kiimikada iyo nano polishing.

Habayn kale oo habaysan iyo dhammays tirsiga codsiga

Daawaynta kulaylka

Deminta faakuumka:Qaybta waxaa lagu kululeeyaa faakuum ka dibna lagu qaboojiyaa gaas qolka qaboojinta.Gaaska dhexdhexaadka ah ayaa loo isticmaalay deminta gaaska, iyo nitrogen saafi ah ayaa loo isticmaalay deminta dareeraha.

Cadaadiska cadaadiska: Kuleylinta walxaha heerkul gaar ah oo ku haynaya wakhti wakhti ah, walbahaarka haraaga ah ee gudaha walaxda waa la tirtiri karaa.

Carbonitriding: Carbonitriding waxaa loola jeedaa habka gelinta kaarboonka iyo nitrogen ee lakabka sare ee birta, taas oo hagaajin karta adkaanta, xoogga, xirashada caabbinta iyo ka hortagga suuxdinta birta.

Daaweynta cryogenic:Nitrojiinka dareeraha ah waxaa loo isticmaalaa qaboojiyaha si loogu daweeyo walxaha ka hooseeya-130 °C, si loo gaaro ujeedada beddelka sifooyinka alaabta.

Xakamaynta tayada

Bartilmaameedka: ciladaha eber

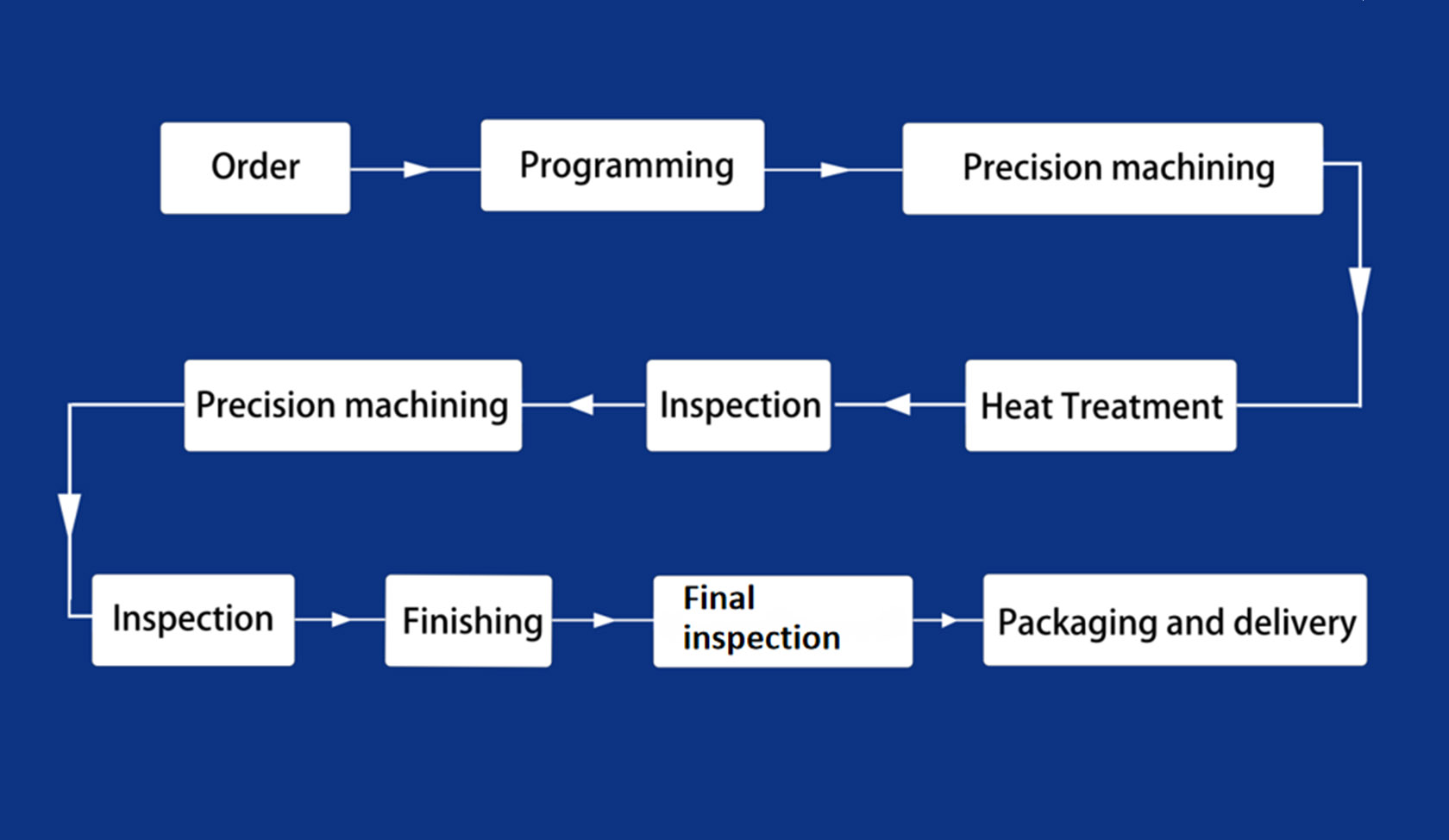

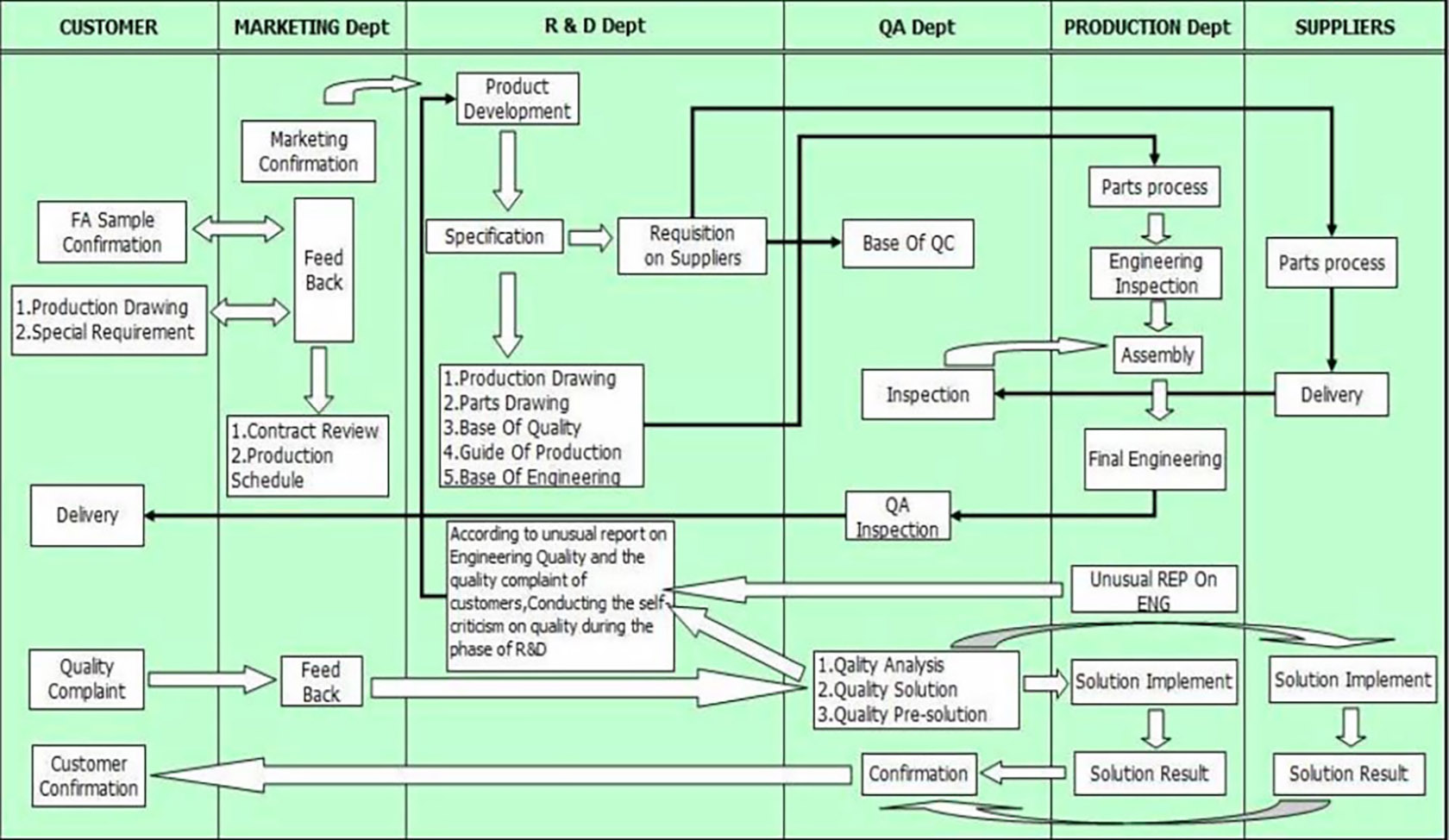

Habsocodka socodka qaybaha iyo nidaamka xakamaynta tayada:

1. Kooxda xakamaynta dukumeentigu waxay maamulaan dhammaan sawirada si ay u dammaanad qaadaan badbaadada macluumaadka qarsoodiga ah ee macmiilka, oo ay hayaan diiwaanka la raadin karo.

2. Dib u eegis qandaraas, dib u eegis iyo dib u eegis nidaamka si loo hubiyo in si buuxda loo fahmo baahida macmiilka.

3. Xakamaynta ECN, ERP bar-code (la xidhiidha shaqaalaha, sawirista, alaabta iyo dhammaan habka).Hirgelinta SPC, MSA, FMEA iyo nidaamka xakamaynta kuwa kale.

4. Hirgeli IQC,IPQC,OQC.

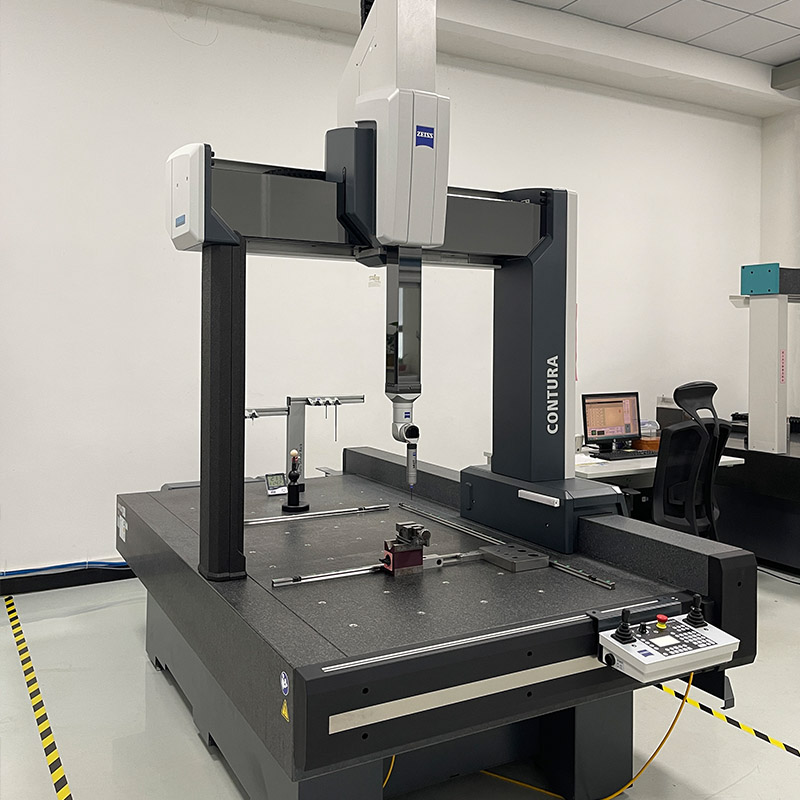

| Nooca Mashiinka | Magaca mashiinka | Summada | Meesha Asal ahaan | Tirada | Saxnimada (mm) |

| Mashiinka Kormeerka Tayada | Saddex Isku-dubarid | Wenzel | Jarmalka | 5 | 0.003mm |

| Zeiss Contura | Jarmalka | 1 | 1.8um | ||

| Qalabka Cabbirka Sawirka | Aragti Wacan | Shiinaha | 18 | 0.005mm | |

| Altimeter | Mitutoyo/Tesa | Japan/Switzerland | 26 | ± 0.001 -0.005mm | |

| Spectrum Analyzer | Spectro | Jarmalka | 1 | - | |

| Tijaabaha qallafsanaanta | Mitutoyo | Japan | 1 | - | |

| Mitirka Dhumucda Filimka Electroplating | - | Japan | 1 | - | |

| Mikrometer Caliper | Mitutoyo | Japan | 500+ | 0.001mm/0.01mm | |

| Cabbirka Irbadda Gauge | Nagoya/Chengdu Qalabka Qiyaasta | Japan/Shiinaha | 500+ | 0.001mm |

Wada sheekaysiga socodka socodka tayada tayada

Socodka Habka Makiinada