Turn-mill CNC muchina chishandiso inzvimbo yakajairwa yekutendeuka-chigayo ine yakanyanya kurongeka, hunyanzvi hwepamusoro, kusimba kwepamusoro, kukwirisa otomatiki uye kuchinjika kwakanyanya.Iyo inotenderedza-milling compound CNC lathe ndeye advanced compound muchina chishandiso chinosanganisira mashanu-axis linkage milling centre uye kaviri-spindle lathe.Inopa mhinduro iri nani yekugadziriswa kwepamusoro-chaiyo, yepamusoro-soro, uye yakanyanya kuoma zvikamu zvidiki.

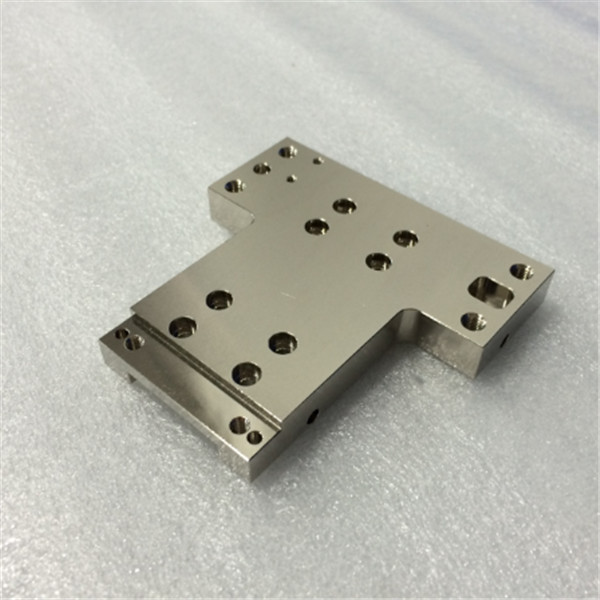

Nekukurumidza kukura kwesainzi uye tekinoroji munyika, zvigadzirwa zvakawanda zviri kusimukira munzira yekunyatso, miniaturization uye huremu huremu.Mazhinji madiki madiki CNC muchina maturusi kazhinji anoda kusangana nezvinodiwa nevashandisi.Munyika yangu yazvino zvigadzirwa zvemuchina, pachine kushomeka kweiyo chaiyo CNC muchina maturusi.Pamusoro pekushandiswa zvakanyanya muindasitiri yewachi, midziyo yekurapa, kugadzira zvikamu zvemotokari uye mamwe maindasitiri emwenje, inogona zvakare kushandiswa mune aerospace, zvombo, ngarava uye dzimwe dziviriro nemauto minda kugadzirisa akawanda akajeka akakosha zvikamu, senge kudzora ndege. gyroscopes, air-to-missile inertial navigation components, inokodzera zvidiki zvakaoma uye zvakaoma zvikamu pamusika.

Iko hakuna zvakakosha zvinodikanwa zvemuchina chishandiso, asi inokwana imwe Y-axis kufamba inofanira kupihwa.Kutenderera kweiyo workpiece kunopa C-axis kufamba kwegayo rekucheka kuti ripe inodiwa chiyero chekudya (simba).Nekudaro, kumhanya kwekucheka kweiyo workpiece kunoyerwa muIPM pane lathe SPM (zvinoreva kuti iyo workpiece yekucheka kumhanya munzvimbo yekugaya yakadzikira zvakanyanya pane kana uchitendeuka).Asi kufamba kweiyo Y axis kwakakosha nekuti mucheki wekugaya anoda yakawanda eccentric machining.

Uyezve, kana chishandiso chiri eccentric, saizi yechikamu inodiwa haigone kugadzirwa, nekuti kana chishandiso chiri pakati, pakati pechishandiso chinopindirana nepakati pekutenderera kwechikamu, saka chishandiso chinogona kungocheka nechiso chekupedzisira. ndiko kuti, haigoni kucheka) uye haigoni kucheka.Cheka mipendero.Chishandiso chepakati chinofanirwa kudzikiswa kubva pachikamu chekutenderera pakati nechikamu chimwe muzvina chedhayamita yemudziyo kuti ive nechokwadi chekucheka kwakaringana nebadza.

Aya matatu anotevera marudzi ezvishandiso anogona kunyatso shandiswa munzvimbo inotenderedza-milling.Chikonzero chikuru chekushandisa wiper blade kana scraper.Kune zvigayo zvekupedzisira zvichichinjana, zvinokwanisika kugadzira chiso chakakura kana kucheka kunorema kunopindirana.Kugaya manera kunoshandisa zvigayo zvekupinza.Solid end mills anoshandiswa kugadzira cylindrical parts, precision milling yakadzika uye nhete migero.

Kushandisa scraper chimiro chechishandiso chataurwa pamusoro apa, kushanda kwepamusoro-soro uye kushandiswa kwepamusoro-soro kunogona kuitika.

Asi nenzira iyi, matambudziko anogona kumuka kana chishandiso chinosvika padyo nemativi ematanho uye grooves.Panguva ino, mushure mekunge eccentric tool yakagadziriswa, makona akawanda akapoteredzwa achasara pamusoro pechikamu.Kuti ubvise mafiritsi aya, chishandiso chinofanira kuvandudzwa.Panguva ino, chishandiso chekugadzirisa hachichadiwi, uye chishandiso chinofamba pamwe neY axis kusvika pakati pechikamu chekugadzira.Zvisinei, mune mamwe matanho ekugadzirisa (dzimwe nguva masimbi haabvumirwi).

Chimwe chechokwadi chisingagutsikane mukutendeuka-milling machining center machining ndiko kukanganisa kwechimiro chezvikamu zvakagadzirwa.Kana chigayo chiri kugaya chakatenderedza chikamu, hazvidzivisiki kuti mamwe ma fan marks anoumbwa pamusoro pechikamu pane dzimwe nguva.Kukanganisa uku hakugone kubviswa zvachose, asi wiper blade inogona kudzorwa zvinobudirira.Iyo blade yakakwenenzverwa inoenderana zvakanyanya nemamwe mablade, kuitira kuti blade isimudzwe zvishoma muhupamhi nzira, kuitira kuti blade yeblade inongoenda kune iyo machined chikamu kuti muchina mutsva blade pamusoro, uye zvishoma feni mamaki akatsetseka.

Nguva yekutumira: Mar-02-2023