A cikin masana'anta, sharuɗɗa uku masu dacewa na ƙayyadaddun kayan aiki, jig, da mold sau da yawa suna bayyana.Don waɗanda ba masana'anta ba, injiniyoyin injiniyoyi ko injiniyoyin injiniyoyi waɗanda ba su da ɗan gogewa a aikace, waɗannan sharuɗɗan uku a wasu lokuta suna rikicewa cikin sauƙi.

Abin da ke gaba shi ne taƙaitaccen gabatarwa, da begen taimaka wa waɗanda suke so su fahimci asali.

Kayan aiki:

Fassarar Ingilishi gama gari shineMatsa, Babban manufar ita ce gyara abubuwa;Ana amfani da manne ba kawai a cikin injuna da kayan aiki ba, amma ana amfani da su sosai a fannoni da yawa.

Misali, tsarin da ke gyara gani akan bindigar ana kiransa tsaiko;aiki ne na asali don gyara abubuwa masu motsi a cikin injina da kayan aiki masu sarrafa kansu.Muddin kayan yana da ƙarfi, babu makawa a gyara abu yayin aiki, taro ko motsi., manufar ita ce hana abu daga motsi ba bisa ka'ida ba lokacin da karfi ko rashin aiki ya canza (hanzari da canje-canje), kuma clamping yana daya daga cikin mahimman hanyoyin gyarawa;a hankali la'akari da ka'idar gyare-gyaren abu, ɗaya daga cikinsu shine don ba da ma'auni na geometric, Ƙarfin yana makale kuma ba zai iya motsawa ba, ɗayan kuma shine samar da matsakaicin matsakaicin ƙarfin juzu'i wanda ya wuce ƙarfin inertial na abu don kauce wa motsi.

Hanyar farko, ƙuntatawa na geometric, ita ce hanya mafi kyau a ka'idar.Dalilin abu ne mai sauqi qwarai, wato, kamar yadda aka sani a al’adance a ilimin kimiyyar lissafi, “kauri ba zai iya wucewa ta cikin daskararru ba”, kuma abubuwa ba za su sami ƙarin tasiri a lokacin motsi ba sai da ƙarfi.karfi, wanda zai iya guje wa abin da ƙarin karfi ya shafa, amma dole ne a tsara abin da aka gyara daidai da siffar abin, kuma ana buƙatar kiyaye haƙuri don jure wa haƙuri da kuskure wajen samar da abu, don haka ba kasafai ake ganinsa a cikin abubuwa na gaske ba.Ana amfani da wannan ƙirar ra'ayi gaba ɗaya.Dalilin shi ne cewa canjin canjin yana da ƙananan ƙananan, kuma kuskuren zai haifar da yiwuwar karo tsakanin abu da kafa.

Hanya ta biyu tana kiyaye ƙayyadaddun matsayi na abu ta hanyar samar da matsakaicin matsakaicin ƙarfin juzu'i wanda ya wuce ƙarfin inertial.Ƙarfin juzu'i da aka bayar ta wannan hanyar yana buƙatar shawo kan tasirin inertial a cikin aƙalla hanyoyi biyu, ɗaya shine alkiblar nauyi, kuma abu ba zai faɗi ƙasa ba., daya shine hanyar motsi (duka fassarar da juyawa ana la'akari da su), ta yadda abu ba zai canza ba yayin hanzari da raguwa, wanda shine mafi mahimmancin hanyar aikace-aikace a halin yanzu.

A al'adance, don kayan ƙarfe, saboda ƙarfin ƙarfin kayan da kansa, ana iya amfani da babban ƙarfi don tabbatar da cewa abu ba zai motsa ba, don haka ana amfani da matsi na hydraulic sau da yawa don gyara abu a cikin wasu kayan aikin sarrafa ƙarfe.

Har ila yau, ya zama ruwan dare a cikin gyaran wasu kayan katako, amma ƙarfin gyarawa zai zama kadan.

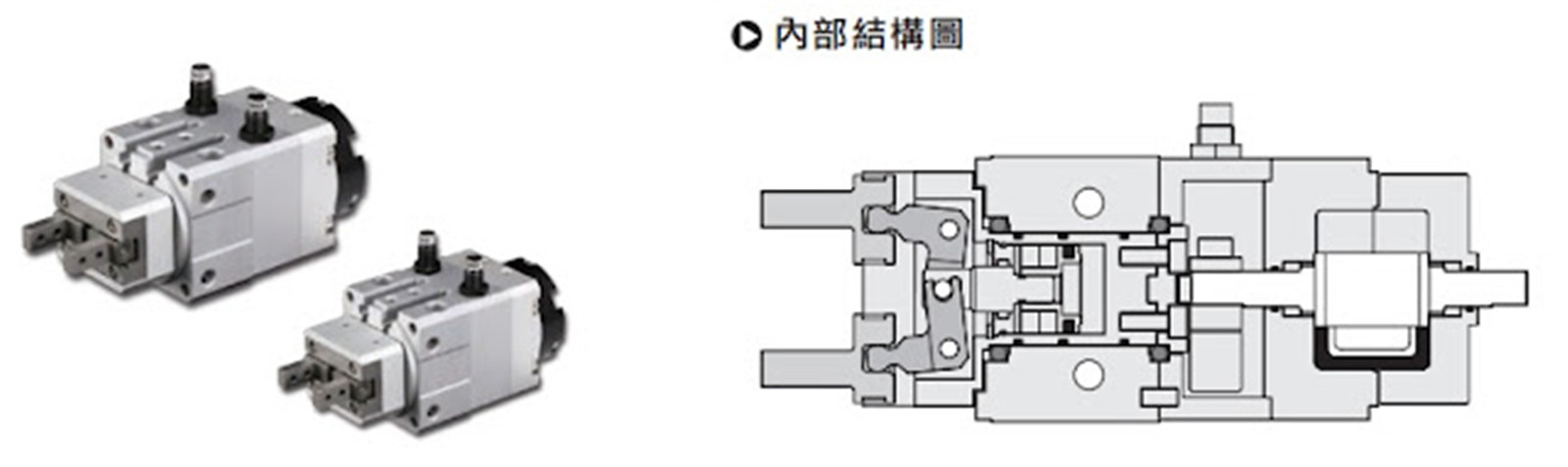

Silinda mai riko da aka nuna a sama na iya kamawa kai tsaye da kuma juya ƙananan abubuwa don sarrafawa

Hanyar da za a ba da matsakaicin ƙarfin juzu'i, ban da samar da ingantaccen ƙarfi a cikin aikin clamping da kuma ninka shi ta hanyar juzu'in juzu'i don ƙididdige matsakaicin matsakaicin ƙarfin juzu'i, a zahiri, yana iya amfani da tsotsawar injin don haifar da matsa lamba. bambanci don samar da ingantaccen ƙarfi, sa'an nan kuma yi aiki tare da babban juzu'i coefficient kayan.Bayar da matsakaicin ƙarfin juzu'i wanda ya wuce ƙarfin inertia.Wannan hanya tana da damar da za ta rage yawan ƙarfin da ake amfani da shi a kan abu.Sabili da haka, ana amfani da shi sau da yawa wajen gyara wasu madaidaicin abubuwan da aka gyara ko kayan da ba su da ƙarfi.Rashin hasara shi ne cewa manyan kayan haɗin gwal za su ragu kuma su gurɓata ko tashe saman abin, waɗanda yakamata a kula da su akan wasu samfuran waɗanda ke buƙatar tsafta mai tsafta.

Daga ra'ayi na gyaran abubuwa yayin motsi, akwai hanya ta musamman don kayan ƙarfe, ciki har da sauran baƙin ƙarfe, cobalt, nickel, da dai sauransu, don amfani da ƙarfin lantarki, wanda aka fi amfani da shi wajen aikin niƙa, niƙa. , shiryawa da sauran kayan aikin injin.A mataki (Magnetic Dutsen),

Duk da haka, wannan karfi yana da girma sosai, kuma yawanci ba a yi amfani da shi don shawo kan ƙarfin motsi ba, amma don shawo kan karfin tsarin yanke.

Ana amfani da ƴan lokuta na musamman a cikin yanayin zafi mai girma, kuma ba za a iya amfani da kayan laushi ba.Har ila yau, akwai wasu wuraren da aka gauraya hanyoyin biyu na sama, kuma ana canza hanya ɗaya zuwa iyakacin lissafi (kamar alkiblar nauyi) don rage tasirin ƙarfi akan abubuwa..

Jig

Sunan turanci da aka saba shineJig, kuma jig ya samo asali ne daga lafazin Jafananci;Babban aikin jig shine gyarawa da gano matsayin abin.Idan aka kwatanta da jig, yana da ƙarin aiki na sakawa, wanda sau da yawa ana gani Jig ɗin zai yi amfani da hanyar ƙuntatawa na geometric don sanya abu, don haka madaidaicin matsayi da fil ɗin sakawa sau da yawa suna da ƙira mara kyau, wanda ake amfani da shi don jagorantar abubuwan. abu a cikin ɗan ƙaramin sarari kuma iyakance matsayin abu.

Don gyara abu daidai, ana ƙara aikin turawa ta tilastawa wani lokaci don sanya abu ya yi daidai da farfajiyar / gefuna;idan wannan aikin ya ci gaba kuma ya hana abu daga motsi, yana aiki kamar tsawo na manne;Sabili da haka, ana haifar da rashin fahimta sau da yawa, kuma daidaitawar yana rikicewa tare da jig.Sabili da haka, magana mai mahimmanci, aiki da maƙasudin ƙayyadaddun kayan aiki da kayan aiki sun ɗan bambanta.Ƙaddamarwa tana mayar da hankali kan gyarawa, kuma kayan aiki yana mai da hankali kan "daidaitaccen matsayi".Duk da haka, saboda kayan aiki wani lokaci yana buƙatar ƙarin ɗaurewa da gyarawa, wani lokaci ana amfani dashi tare da kayan aiki.Zai yi kama da ɗan kama;a aikace, ana sanya tsarin ƙirar biyun a cikin sashe ɗaya a cikin masana'anta, wanda ake kira ƙirar ƙirar.Ana iya sanya wannan sashin a cikin samarwa, kula da kayan aiki, ko ma a cikin al'amuran masana'anta ko A cikin bincike da haɓaka samfura, asalin ilimin ilimi galibi injiniyan injiniya ne.

Ƙimar haɓakawa da ƙira shine muhimmin mahimmancin farawa a cikin haɓaka kayan aiki na atomatik.Yawancin kamfanonin kayan aiki na atomatik suna farawa daga taimakawa masana'antu don ingantawa da tsara kayan aikin da aka shigo da su, da na'urorin tuƙi da da'irori masu sarrafawa.Bayan duk hanyar, tara samfuri da ƙwarewar kayan aiki kuma ku zama cikakken kamfanin kayan aikin sarrafa kansa.

m

Sunan IngilishiMold, Menene?Ayyukan kayan aiki na baya shine yafi gyarawa da matsayi, m ba shi da wani tasiri akan samfurin kuma ba zai shafi samfurin da kansa ba, amma ƙirar ta bambanta, kuma ƙirar za ta shiga kai tsaye a cikin tsarin masana'antu.

Akwai nau'ikan gyare-gyare iri-iri, amma babban aikin shine iyakance sifar samfur, ko siffanta kayan da ake buƙata zuwa siffar da ake so.Da sauransu shine misali mafi sauƙin fahimta, don haka ana iya cewa gyaggyarawa a ko'ina wajen kera kaya.Babban abin da ya fi shahara shi ne, gyare-gyaren katako da ake amfani da su don yin biredin wata ma wani nau'i ne.Muddin an sayar da adadi mai yawa na ƙira don ƙare masu amfani Don kera kayayyaki, za a sami wata siffa, kuma wannan siffa dole ne a cika ta da mold.

Za a ƙayyade rarrabuwa na ƙira bisa ga masana'antu da tsarin da aka zaɓa.Baya ga kayan kwalliyar abinci, akwai nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan masana'antu: filastik da karfe (ba shakka, sauran yumbu, kayan kwalliya, da sauransu kuma za su yi amfani da gyaggyarawa) , amma adadin yana da ɗan ƙaramin ƙarfi), don haka. da farko a taƙaice gabatar da mafi girman adadin masana'antar filastik a cikin 'yan shekarun nan.Molds don masana'antar ƙarfe ko masana'anta filastik za a iya rarraba su daban-daban dangane da tsari.

Lokacin aikawa: Dec-21-2022