Kwimveliso, imimiselo emithathu efanelekileyo yokulungiswa, i-jig, kunye ne-mold ihlala ibonakala.Ukwenzela izinto ezingenzi mveliso, iinjineli zoomatshini okanye iinjineli zoomatshini ezinamava amancinci asebenzayo, la magama mathathu ngamanye amaxesha abhideka ngokulula.

Oku kulandelayo yintshayelelo emfutshane, ngethemba lokunceda abo banomdla ukuba babe nokuqonda okusisiseko.

Ukulungiswa:

Inguqulelo yesiNgesi eqhelekileyo yileUkubamba, injongo ephambili kukulungisa izinto;Iiclamps azisetyenziswa kuphela koomatshini bokuvelisa kunye nezixhobo, kodwa zisetyenziswa ngokubanzi kwiindawo ezininzi.

Umzekelo, ulwakhiwo olulungisa imbonakalo yompu lubizwa ngokuba luphawu;ngumsebenzi osisiseko kakhulu ukulungisa izinto ezihambayo kumatshini kunye nezixhobo ezizenzekelayo.Ngethuba nje izinto eziphathekayo ziqinile, akunakuphepheka ukulungisa into ngexesha lokucubungula, ukudibanisa okanye ukunyakaza., injongo kukuthintela into ekutshintsheni ngokungaqhelekanga xa amandla okanye inertia itshintsha (ukukhawuleza kunye nokunciphisa utshintsho), kunye ne-clamping enye yezona ndlela zibalulekileyo zokulungiswa;qwalasela ngononophelo umgaqo wokulungiswa kwezinto, enye yazo kukunika imiqobo yejometri, I-solid ibambekile kwaye ayikwazi ukuhamba, kwaye enye kukubonelela ngowona mandla ogqwesileyo we-static ogqithisa amandla angenayo ento ukuphepha ukunyakaza.

Indlela yokuqala, isithintelo sejometri, yindlela engcono kakhulu kwithiyori.Isizathu silula kakhulu, oko kukuthi, njengoko kwaziwa ngokwesiko kwi-physics, "izinto eziqinileyo azikwazi ukudlula kwizinto eziqinileyo", kwaye izinto aziyi kuthotyelwa kwimiphumo eyongezelelweyo ngexesha lokunyakaza ngaphandle kwamandla angenayo.amandla, anokuthi aphephe into echaphazelekayo ngamandla ongezelelweyo, kodwa ukulungiswa kufuneka kuyilwe ngokwemilo yento, kwaye ukunyamezela kufuneka kugcinwe ukujamelana nokunyamezela kunye nempazamo kwimveliso yento, ngoko ke ayifane ibonwe kwizinto zokwenyani.Le ngcamango yoyilo isetyenziswe ngokupheleleyo.Isizathu kukuba utshintsho lwe-elasticity luncinci kakhulu, kwaye impazamo iya kubangela ukuba kwenzeke ukungqubana phakathi kwento kunye nokulungiswa.

Indlela yesibini igcina indawo emiselweyo yento ngokubonelela ngowona mandla uphezulu we-static friction odlula amandla angenayo.Amandla okukhuhlana anikezelwe yile ndlela kufuneka anqobe umphumo we-inertial ubuncinane kwiindlela ezimbini, enye isalathiso sobunzima, kwaye into ayiyi kuwela phantsi., enye isalathiso sokunyakaza (kokubini ukuguqulelwa kunye nokujikeleza kuqwalaselwa), ukwenzela ukuba into ayiyi kutshintsha ngexesha lokukhawuleza kunye nokunciphisa, eyona ndlela ibaluleke kakhulu yesicelo ngoku.

Ngokwesiko, kwizinto zetsimbi, ngenxa yamandla aphezulu ezinto ngokwawo, amandla amakhulu angasetyenziswa ukuze kuqinisekiswe ukuba into ayiyi kuhamba, ngoko ke i-clamps ye-hydraulic isoloko isetyenziselwa ukulungisa into kwezinye izixhobo ze-automation processing metal.

Kuqhelekile kwakhona ekulungiseni ezinye izinto zokhuni, kodwa amandla okulungisa aya kuba ncinane.

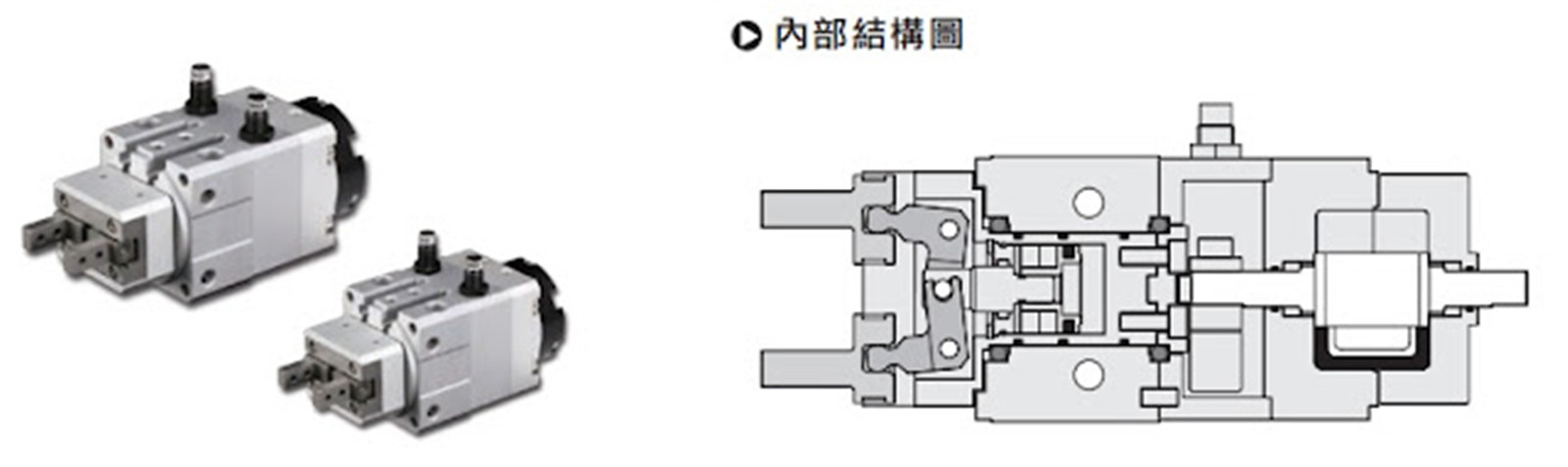

I-cylinder yokubamba eboniswe ngasentla inokubamba ngokuthe ngqo kwaye ijikeleze izinto ezincinci zokuphatha

Indlela yokubonelela ngowona mandla uphezulu wefriction engatshintshiyo, ukongeza ekunikeni amandla alungileyo kwisenzo sokubamba kunye nokuphinda-phinda nge-coefficient yokukhuhlana ukubala ubuninzi bamandla okukhuhla okumileyo, enyanisweni, inokusebenzisa ukufunxa kwevacuum ukuvelisa uxinzelelo. Umahluko ukubonelela ngamandla afanelekileyo, kwaye emva koko usebenzisane ne-coefficient ye-coefficient material ephezulu.Ukubonelela ngowona mandla okrwadayo angatshintshiyo angaphaya kwamandla e-inetia.Le ndlela inethuba lokunciphisa inani lamandla asetyenziswe kwinto.Ke ngoko, isetyenziswa rhoqo ekulungiseni amanye amacandelo achanekileyo okanye izinto ezibhityileyo.Ukungalungi kukuba i-friction coefficients ephezulu iya kuhlala kwaye ingcolise okanye ikrwele umphezulu wento, ekufuneka ithathelwe ingqalelo kwezinye iimveliso ezifuna ukucoceka okuphezulu kakhulu.

Ukusuka kwindawo yokujonga izinto ngexesha lokuhamba, kukho indlela ekhethekileyo yezinto zentsimbi, kubandakanywa nezinye isinyithi samagnetic, i-cobalt, i-nickel, njl., ukusebenzisa amandla e-electromagnetic force, esetyenziswa ngokuqhelekileyo kumsebenzi wokugaya, ukugaya , ukucwangcisa kunye nezinye izixhobo zoomatshini.Kwiqonga (intaba yemagnethi),

Nangona kunjalo, eli gunya likhulu kakhulu, kwaye ngokuqhelekileyo alisetyenziselwa ukunqoba amandla angenayo intshukumo, kodwa ukunqoba amandla enkqubo yokusika.

Amatyala ambalwa akhethekileyo asetyenziswa kwiindawo eziphakamileyo zokushisa, kwaye izinto ezithambileyo azikwazi ukusetyenziswa.Kukho nezinye izigcawu apho iindlela ezimbini ezingentla zixutywe, kwaye enye isalathiso iguqulwa ibe ngumda wejometri (njengesalathiso sobunzima) ukunciphisa impembelelo yamandla kwizinto..

Jig

Igama lesiNgesi eliqhelekileyo nguJig, kwaye i-jig ithathwe kwi-pronunciation yesiJapan;umsebenzi oyintloko we-jig kukulungisa kunye nokubeka indawo yento.Xa kuthelekiswa ne-jig, inomsebenzi owongezelelweyo wokumisa, odla ngokubonakala I-jig iya kusebenzisa indlela yokuthintela ijometri yokubeka into, ngoko ibhloko yokumisa kunye nepini yokubeka ihlala inoyilo oluthambekileyo, olusetyenziselwa ukukhokela into kwisithuba esincinci kwaye unciphise indawo yento.

Ukuze kulungiswe into ngokuchanekileyo, isenzo sokutyhala ngenkani ngamanye amaxesha siyongezwa ukwenza into ihambelane nomgangatho wereferensi / edge;ukuba esi senzo siyaqhubeka kwaye sithintela into ukuba ihambe, isebenza njengokwandiswa kwe-clamp;Ngoko ke, ukungaqondi kakuhle kubangelwa rhoqo, kwaye ukulungiswa kudidekile kunye nejig.Ke ngoko, xa sithetha ngokungqongqo, umsebenzi kunye nenjongo yefixture kunye ne-fixture yahluke kancinane.Umzobo ugxile ekulungiseni, kwaye umzobo ugxile ekumisweni "okuchanekileyo".Nangona kunjalo, ngenxa yokuba ukulungiswa ngamanye amaxesha kufuna ukubethelwa ngakumbi kunye nokulungiswa, ngamanye amaxesha kusetyenziswa kunye ne-fixture.Iya kufana kancinci;ngokwenza, uyilo lwesixhobo sokubini luhlala lubekwe kwisebe elifanayo kumzi-mveliso, obizwa ngokuba yi-fixture design.Eli sebe linokubekwa kwimveliso, ukugcinwa kwezixhobo, okanye nakwimicimbi yefektri okanye kuphando lwemveliso kunye nophuhliso, imvelaphi yemfundo esisiseko ikakhulu yinjineli yoomatshini.

Ukuphuculwa kokulungiswa kunye noyilo luyisiqalo esibaluleke kakhulu ekuphuhliseni izixhobo ezizenzekelayo.Iinkampani ezininzi zezixhobo ze-automation ziqala ekuncedeni iifektri ukuba ziphucule kwaye ziyilwe izixhobo ezisuka kwamanye amazwe, kunye nezixhobo zokuqhuba kunye neesekethe zokulawula.Emva kwayo yonke indlela, qokelela amava emveliso kunye nezixhobo kwaye ube yinkampani epheleleyo yezixhobo ezizenzekelayo.

ngundo

Igama lesiNgesiNgundo, Yintoni?Umsebenzi wokulungiswa kwangaphambili ngokuyinhloko ulungisa kunye nokubeka, ngokusisiseko awunayo enye impembelelo kwimveliso kwaye ayiyi kuchaphazela ngokuthe ngqo imveliso ngokwayo, kodwa i-mold ihluke, kwaye isikhunta siya kuthatha inxaxheba ngokuthe ngqo kwinkqubo yokuvelisa.

Kukho iintlobo ezininzi zokubumba, kodwa umsebenzi osisiseko kukunciphisa imilo yemveliso, okanye ukubumba imathiriyeli ekrwada ibe yimo efunekayo.Etc. ngowona mzekelo ulula ukuqondwa, ngoko ke iimolds zinokuthiwa zikho kuyo yonke indawo ekwenziweni kwempahla.Eyona nto idumileyo kukuba iimbumba zomthi ezisetyenziselwa ukwenza amaqebengwana enyanga nazo luhlobo lokubumba.Ngethuba nje inani elikhulu lokubumba ekugqibeleni lithengiswa kubathengi bokugqibela Ukuvelisa iimpahla, kuya kuba nemilo ethile, kwaye le milo kufuneka igqitywe ngumbumba.

Ulwahlulo lokubumba luya kumiselwa ngokweshishini kunye nenkqubo ekhethiweyo.Ngaphandle kokubumba ukutya, kukho iindidi ezimbini eziphambili zezinto ezicutshungulwa ngumbumba kwishishini lokuvelisa: iplastiki kunye nesinyithi (ngokuqinisekileyo, ezinye iiseramics, izinto ezidibeneyo, njl njl. ziya kusebenzisa i-molds) , kodwa isixa sincinci), ngoko ke okokuqala kwazisa ngokufutshane elona nani likhulu lokungunda kweplastiki kumashumi eminyaka akutshanje.Iimbumba zokwenza isinyithi okanye ukwenziwa kweplastiki zingahlelwa ngokwahlukileyo kuxhomekeke kwinkqubo.

Ixesha lokuposa: Dec-21-2022