Hauv kev tsim khoom, peb cov ntsiab lus tsim nyog ntawm fixture, jig, thiab pwm feem ntau tshwm sim.Rau cov uas tsis yog-tsim, mechanical engineers lossis mechanical engineers nrog me ntsis kev paub, cov ntsiab lus no qee zaum yooj yim tsis meej pem.

Cov hauv qab no yog cov lus qhia luv luv, vam tias yuav pab cov neeg nyiam kom muaj kev nkag siab yooj yim.

Fixtures:

Cov lus txhais lus Askiv feem ntau yogClamp, lub hom phiaj tseem ceeb yog kho cov khoom;Clamps tsis yog tsuas yog siv nyob rau hauv ntau lawm machinery thiab khoom, tab sis kuj lug siv nyob rau hauv ntau lub teb.

Piv txwv li, cov qauv uas kho qhov pom ntawm rab phom yog hu ua fixture;Nws yog ib qho tseem ceeb heev ua haujlwm los txhim kho cov khoom txav hauv cov tshuab thiab cov cuab yeej siv.Raws li ntev raws li cov khoom muaj zog, nws yog ib qho tsim nyog yuav tsum kho cov khoom thaum lub sij hawm ua, sib dhos lossis txav mus los., lub hom phiaj yog los tiv thaiv cov khoom los ntawm kev hloov arbitrarily thaum lub zog los yog inertia hloov (acceleration thiab deceleration hloov), thiab clamping yog ib qho tseem ceeb tshaj plaws kho txoj kev;Ua tib zoo xav txog lub hauv paus ntsiab lus ntawm kev kho cov khoom, ib qho yog muab geometric txwv, cov khoom yog daig thiab txav tsis tau, thiab lwm yam yog muab qhov siab tshaj plaws kev sib txhuam quab yuam uas tshaj qhov inertial quab yuam ntawm cov khoom kom tsis txhob txav mus los.

Thawj txoj kev, kev txwv geometrical, yog txoj kev zoo tshaj plaws hauv kev xav.Qhov laj thawj yog qhov yooj yim heev, uas yog, raws li ib txwm paub hauv physics, "khoom tsis tuaj yeem dhau los ntawm cov khoom khib nyiab", thiab cov khoom yuav tsis raug cuam tshuam ntxiv thaum lub zog txav tshwj tsis yog lub zog inertial.quab yuam, uas tuaj yeem zam qhov khoom raug cuam tshuam los ntawm kev quab yuam ntxiv, tab sis lub fixture yuav tsum tau tsim raws li qhov zoo ntawm cov khoom, thiab kev kam rau siab yuav tsum tau tshwj tseg los tiv thaiv kev kam rau siab thiab ua yuam kev hauv kev tsim cov khoom, yog li nws tsis tshua pom hauv cov khoom tiag.Lub tswv yim tsim no yog siv tag nrho.Yog vim li cas yog qhov hloov elasticity me me dhau lawm, thiab qhov yuam kev yuav ua rau muaj peev xwm ntawm kev sib tsoo ntawm cov khoom thiab lub fixture.

Qhov thib ob txoj kev tswj xyuas qhov chaw ruaj khov ntawm qhov khoom los ntawm kev muab qhov siab tshaj plaws static kev sib txhuam quab yuam uas tshaj qhov inertial quab yuam.Kev sib txhuam quab yuam muab los ntawm txoj kev no yuav tsum kov yeej cov nyhuv inertial tsawg kawg yog ob qho kev qhia, ib qho yog kev taw qhia ntawm lub ntiajteb txawj nqus, thiab cov khoom yuav tsis poob., ib qho yog cov kev taw qhia txav (ob qho tib si txhais lus thiab kev sib hloov yog txiav txim siab), yog li ntawd cov khoom yuav tsis hloov thaum lub sij hawm acceleration thiab deceleration, uas yog qhov tseem ceeb tshaj plaws daim ntawv thov txoj kev tam sim no.

Kev lig kev cai, rau cov khoom siv hlau, vim tias lub zog siab ntawm cov khoom nws tus kheej, lub zog loj tuaj yeem siv los xyuas kom meej tias cov khoom yuav tsis txav mus, yog li hydraulic clamps feem ntau siv los kho cov khoom hauv qee cov khoom siv hlau ua automation.

Nws kuj tseem muaj nyob rau hauv fixation ntawm ib co khoom ntoo, tab sis lub fixation quab yuam yuav kuj me me.

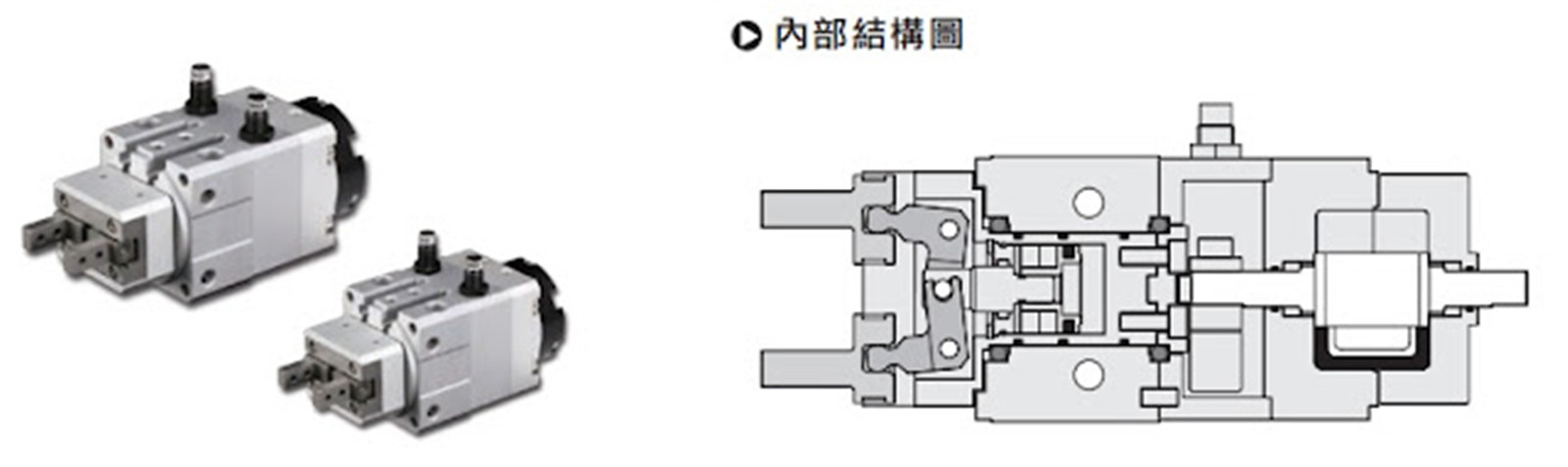

Lub gripper lub tog raj kheej qhia saum toj no tuaj yeem tuav ncaj qha thiab tig cov khoom me me rau kev tuav

Txoj kev los muab qhov siab tshaj plaws kev sib txhuam quab yuam, ntxiv rau kev muab lub zog zoo hauv qhov kev ua haujlwm clamping thiab muab nws los ntawm kev sib txhuam coefficient los xam qhov siab tshaj plaws kev sib txhuam quab yuam, qhov tseeb, nws kuj tuaj yeem siv lub tshuab nqus tsev nqus los ua kom lub siab. sib txawv los muab lub zog zoo, thiab tom qab ntawd koom tes nrog cov khoom siv sib txhuam coefficient siab.Muab qhov siab tshaj plaws kev sib txhuam quab yuam uas tshaj lub zog inertia.Txoj kev no muaj lub cib fim los txo tus nqi ntawm lub zog siv rau cov khoom.Yog li ntawd, nws yog feem ntau siv nyob rau hauv kev kho ntawm ib co precision Cheebtsam los yog nkig cov ntaub ntawv.Qhov tsis zoo yog tias cov ntaub ntawv sib txhuam coefficient siab yuav Residue thiab paug los yog khawb qhov saum npoo ntawm cov khoom, uas yuav tsum tau them sai sai rau qee yam khoom uas yuav tsum tau ua kom huv huv.

Los ntawm qhov pom ntawm kev kho cov khoom thaum lub sijhawm txav mus los, muaj ib txoj hauv kev tshwj xeeb rau cov khoom siv hlau, nrog rau lwm cov hlau nplaum hlau, cobalt, npib tsib xee, thiab lwm yam, siv electromagnetic quab yuam, uas feem ntau siv rau hauv kev ua haujlwm ntawm milling, sib tsoo. , kev npaj thiab lwm yam cuab yeej tshuab.Nyob rau theem (magnetic mount),

Txawm li cas los xij, lub zog no loj heev, thiab feem ntau tsis siv los kov yeej lub zog inertial ntawm lub zog, tab sis kom kov yeej lub zog ntawm cov txheej txheem txiav.

Ob peb qhov tshwj xeeb yog siv nyob rau hauv qhov kub thiab txias, thiab cov ntaub ntawv mos siv tsis tau.Kuj tseem muaj qee qhov xwm txheej uas ob txoj hauv kev saum toj no sib xyaw, thiab ib qho kev taw qhia tau hloov mus rau qhov txwv geometric (xws li kev taw qhia ntawm lub ntiajteb txawj nqus) kom txo qhov cuam tshuam ntawm quab yuam ntawm cov khoom..

Jig

Lub npe lus Askiv ib txwm yogJig, thiab jig yog muab los ntawm cov lus Japanese;lub luag haujlwm tseem ceeb ntawm jig yog kho thiab nrhiav qhov chaw ntawm qhov khoom.Piv nrog rau jig, nws muaj ib qho kev ua haujlwm ntxiv ntawm qhov chaw, uas feem ntau pom Lub jig yuav siv txoj kev txwv geometric los tso cov khoom, yog li qhov chaw thaiv qhov chaw thiab tus pin positioning feem ntau muaj cov qauv sloped, uas yog siv los coj cov khoom. yam khoom rau hauv qhov chaw me me thiab txwv txoj haujlwm ntawm qhov khoom.

Txhawm rau txhim kho cov khoom kom meej meej, qee zaum kev quab yuam thawb yog ntxiv los ua kom cov khoom abut tiv thaiv qhov siv qhov chaw / ntug;yog tias qhov kev txiav txim no txuas ntxiv thiab tiv thaiv cov khoom txav mus los, nws ua haujlwm zoo li txuas ntxiv ntawm qhov clamp;Yog li ntawd, kev nkag siab yuam kev feem ntau tshwm sim, thiab lub fixture tsis meej pem nrog lub jig.Yog li ntawd, nruj me ntsis hais lus, kev ua haujlwm thiab lub hom phiaj ntawm lub fixture thiab lub fixture yog txawv me ntsis.Lub fixture tsom rau kev kho, thiab lub fixture tsom rau ntawm "precise" positioning.Txawm li cas los xij, vim hais tias lub fixture tej zaum yuav tsum tau ntau clamping thiab kho, nws yog tej zaum siv nrog fixture.Nws yuav zoo ib yam;nyob rau hauv kev xyaum, lub mechanism tsim ntawm ob feem ntau muab tso rau hauv tib lub department nyob rau hauv lub Hoobkas, hu ua fixture tsim.Lub chaw haujlwm no tuaj yeem muab tso rau hauv kev tsim khoom, kev saib xyuas cov khoom siv, lossis txawm tias nyob rau hauv kev ua haujlwm hauv lub Hoobkas lossis hauv kev tshawb fawb thiab kev tsim khoom, cov kev kawm keeb kwm yav dhau los yog cov kws ua haujlwm kho tshuab.

Fixture txhim kho thiab tsim qauv yog qhov pib tseem ceeb heev hauv kev tsim cov khoom siv tsis siv neeg.Ntau lub tuam txhab khoom siv automation pib los ntawm kev pab cov chaw tsim khoom los txhim kho thiab tsim cov khoom siv txawv teb chaws, ntxiv rau cov khoom siv tsav tsheb thiab tswj cov circuits.Tom qab tag nrho txoj kev, sau cov khoom thiab cov cuab yeej kev paub thiab dhau los ua ib lub tuam txhab ua tiav automation khoom.

pwm

Lub npe AskivPwm, yog dab tsi?Kev ua haujlwm ntawm kev sib tw dhau los yog kev kho thiab qhov chaw, feem ntau nws tsis muaj lwm yam cuam tshuam rau cov khoom thiab yuav tsis cuam tshuam ncaj qha rau cov khoom nws tus kheej, tab sis cov pwm txawv, thiab cov pwm yuav ncaj qha koom rau hauv cov txheej txheem tsim khoom.

Muaj ntau ntau hom pwm, tab sis lub hauv paus muaj nuj nqi yog txwv tsis pub cov duab ntawm cov khoom, los yog tsim cov ntaub ntawv raw rau hauv cov duab xav tau.Etc. yog qhov piv txwv yooj yim tshaj plaws rau kev nkag siab, yog li cov pwm tuaj yeem hais tau nyob rau hauv kev tsim khoom.Qhov nrov tshaj plaws yog cov ntoo pwm uas siv los ua lub hli ncuav mog qab zib kuj yog hom pwm.Ntev npaum li tus naj npawb ntawm cov pwm thaum kawg raug muag rau cov neeg siv khoom kawg Los tsim cov khoom, yuav muaj ib qho zoo, thiab cov duab no yuav tsum ua kom tiav los ntawm pwm.

Kev faib tawm ntawm cov pwm yuav raug txiav txim raws li kev lag luam thiab cov txheej txheem xaiv.Sib nrug los ntawm cov khoom noj pwm, muaj ob lub ntsiab ntawm cov ntaub ntawv ua tiav los ntawm pwm hauv kev tsim khoom lag luam: yas thiab hlau (ntawm chav kawm, lwm yam ceramics, cov ntaub ntawv sib xyaw, thiab lwm yam yuav siv pwm), tab sis tus nqi me me), yog li. thawj zaug qhia luv luv qhia txog qhov loj tshaj plaws ntawm cov yas tsim pwm nyob rau hauv xyoo tsis ntev los no.Moulds rau kev tsim hlau lossis kev tsim khoom yas tuaj yeem raug cais tawm txawv nyob ntawm tus txheej txheem.

Post lub sij hawm: Dec-21-2022