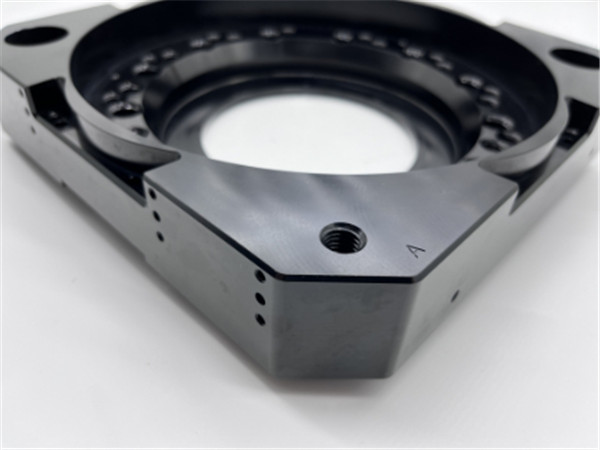

5-axis machining machine to quickly and efficiently manufacture complex milled parts in small batches from a variety of materials. Using 5-axis precision machining is often a more efficient way to make difficult parts with multi-angle features

5-axis precision machining

Machining complex components is usually time-consuming. The more surfaces a component has, the more difficult it is to machine, and various problems are prone to occur during reprocessing. The way to avoid these problems is to use a 5-axis precision machining machine, in which the machine tool moves the machining tool along 5 different axes at the same time. This means workers need to reposition components with less complex setups, and complex parts can be machined easily and accurately without moving components during machining.

5-axis precision machining

Machinists are using 5-axis precision machining machines to rapidly mill aluminum, steel, titanium, copper, brass, engineering plastics and more into complex shapes. Including the automotive, aerospace components and medical equipment fields and many other fields that require 5-axis precision machining.

5-axis precision machining for complex models

5-axis precision machining is often used to quickly complete complex prototypes or low-volume parts. Machining precision parts in various industries from solid billets, because they are often much stronger than parts made from multiple parts, using 5-axis precision machining means This can speed up the manufacturing process by reducing setup time and machine features on different sides.

Milling with 5-axis precision machining speeds up the manufacturing process of complex precision parts, revolutionizing industry machining efficiency. It also allows designers to consider previously impossible or uneconomical designs, and quality parts that can be produced in solid billet, rather than cast workpieces with associated drawbacks. For example, impellers, extruder screws, turbine blades and propellers with demanding geometries can be machined from any solid material that can be machined using high performance carbide tools. Almost any shape and geometry is possible.

Post time: Mar-03-2023