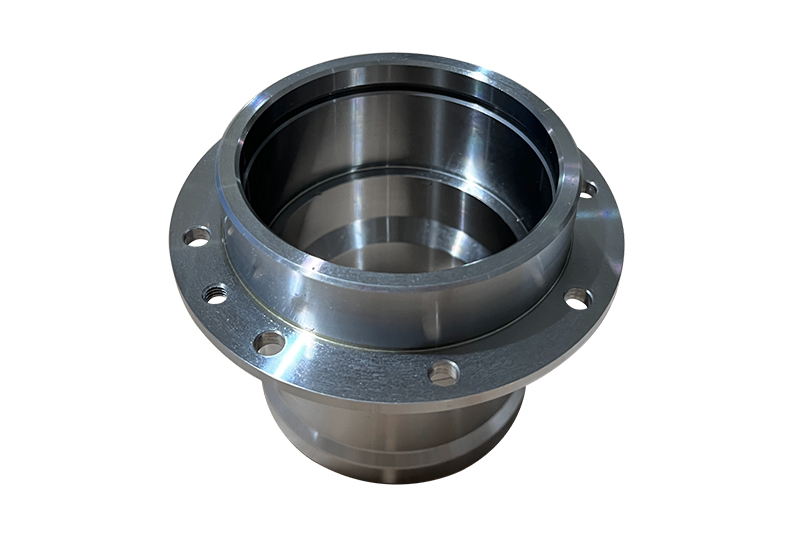

Lager flansch/bearing flange/Robotics precision part

Description

A robot bearing flange is a component specifically designed to support and bear the load of a robot arm. It is usually made of metal material, has a circular shape and a central hole, and is used to connect the robot arm to other robot components. The bearing flange must have highly precise geometric shape and dimensions to ensure the accuracy and stability of the robot. It must also be able to withstand the weight and torque of the robot to ensure smooth and precise robot motion. Therefore, manufacturing robot bearing flanges is a technically complex and precision-demanding process.

Application

Robotic bearing flanges are critical components in robot systems, typically used to support and carry the robot arm and connect other robot components. Its application is very extensive, including but not limited to the following fields:

Industrial Automation: Robotic bearing flanges can be used in various industrial automation scenarios, such as automobile manufacturing, electronic product manufacturing, and food processing, etc.

Healthcare: Robots are increasingly used in the healthcare field, such as surgical robots, rehabilitation robots, etc. Robotic bearing flanges play an important role in these robots.

Military Applications: Robotic bearing flanges can also be used in military applications, such as military robots, drones, etc.

Custom Processing of High-precision Machining Parts

|

Machinery Process |

Materials Option |

Finish Option |

||

| CNC Milling CNC Turning CNC Grinding Precision Wire Cutting |

Aluminum alloy |

A6061,A5052,2A17075 , etc. |

Plating |

Galvanized, Gold Plating, Nickel Plating, Chrome Plating, Zinc nickel alloy, Titanium Plating,Ion Plating |

|

Stainless steel |

SUS303,SUS304,SUS316,SUS316L,SUS420,SUS430,SUS301,etc. |

Anodized |

Hard oxidation ,Clear Anodized,Color Anodized |

|

|

Carbon steel |

20#、45#,etc. |

Coating |

Hydrophilic coating、Hydrophobic coating、Vacuum coating、Diamond Like Carbon(DLC)、PVD (Golden TiN; Black:TiC, Silver:CrN) |

|

|

Tungsten steel |

YG3X,YG6,YG8,YG15,YG20C,YG25C |

|||

|

Polymer material |

PVDF、PP、PVC、PTFE、PFA、FEP、ETFE、EFEP、CPT、PCTFE、PEEK |

Polishing |

Mechanical polishing, electrolytic polishing, chemical polishing and nano polishing |

|

Processing Capacity

|

Technology |

Machine List |

Service |

|

CNC Milling |

Five-axis Machining |

Service Scope:Prototype & Mass Production |

Frequently Asked Questions

1.Question: What types of parts can you process?

Answer: We can process various types of parts made of materials such as metal, plastic, and ceramics. We strictly follow the design drawings provided by the customer to perform machining according to their requirements.

2.Question: What is your production lead time?

Answer: Our production lead time will depend on the complexity, quantity, material, and customer requirements of the parts. Typically, we can complete the production of ordinary parts in 5-15 days at the fastest. For urgent tasks and products with complex machining difficulty, we can try to shorten the delivery lead time.

3.Question: Are the parts comply with relevant standards?

Answer: We adopt strict quality control measures and inspection standards during the production process to ensure the quality.

4.Question: Do you offer sample production services?

Answer: Yes, we offer sample production services. Customers can provide us with design drawings and sample requirements, and we will carry out production and processing, and conduct testing and inspection to ensure that the samples meet customer requirements and standards.

5.Question: Do you have automated machining capabilities?

Answer: Yes, we have various advanced automated machining equipment, which can improve production efficiency and accuracy. We constantly update and upgrade equipment and technology to meet the needs of customers.

6.Question: What after-sales services do you provide?

Answer: We provide complete after-sales services, including product installation, commissioning, maintenance, and repair, etc. We also provide technical support and guidance to ensure that customers get the best user experience and product value.