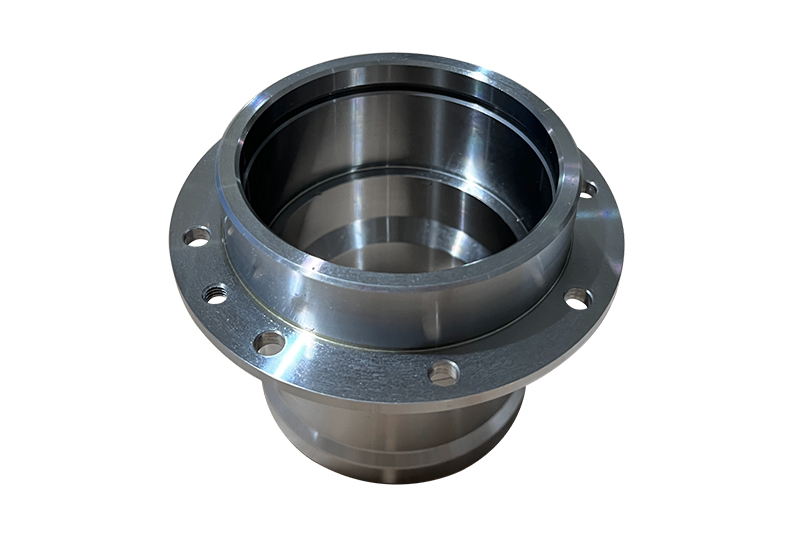

Lager flansch/bearing flange/Karolo e nepahetseng ea liroboto

Tlhaloso

Roboto e nang le flange ke karolo e etselitsoeng ka ho khetheha ho tšehetsa le ho jara mojaro oa letsoho la roboto.Hangata e entsoe ka thepa ea tšepe, e na le sebōpeho sa selikalikoe le lesoba le bohareng, 'me e sebelisetsoa ho hokahanya letsoho la robot ho likarolo tse ling tsa roboto.The bearing flange e tlameha ho ba le sebopeho se nepahetseng haholo sa geometri le litekanyo ho netefatsa ho nepahala le botsitso ba roboto.E tlameha hape ho khona ho mamella boima le torque ea roboto ho netefatsa motsamao o bonolo le o nepahetseng oa roboto.Ka hona, ho etsa liroboto tse nang le li-flange ke ts'ebetso e rarahaneng le e hlokang ho nepahala.

Kopo

Li-flange tse nang le liroboto ke likarolo tsa bohlokoa lits'ebetsong tsa liroboto, tseo hangata li sebelisetsoang ho ts'ehetsa le ho nka letsoho la roboto le ho hokahanya likarolo tse ling tsa liroboto.Tšebeliso ea eona e pharaletseng haholo, ho kenyelletsa empa ha e felle feela libakeng tse latelang:

Industrial Automation:Li-flange tse nang le liroboto li ka sebelisoa maemong a fapaneng a liindasteri, joalo ka ho etsa likoloi, ho etsa lihlahisoa tsa elektroniki, le ho lokisa lijo, jj.

Tlhokomelo ea bophelo:Liroboto li ntse li sebelisoa ka ho eketsehileng lefapheng la tlhokomelo ea bophelo, tse kang liroboto tsa ho buoa, liroboto tsa ho tsosolosa, joalo-joalo. Li-flange tse nang le liroboto li phetha karolo ea bohlokoa ho liroboto tsena.

Likopo tsa Sesole:Li-flange tse nang le liroboto li ka sebelisoa lits'ebetsong tsa sesole, joalo ka liroboto tsa sesole, li-drones, jj.

Ts'ebetso e Tloaelehileng ea Likarolo tsa ho sebetsa ka mokhoa o nepahetseng haholo

| Mokhoa oa mechine | Khetho ea Lisebelisoa | Qetella Khetho | ||

| CNC Milling Ho fetoha ha CNC CNC Ho sila Precision Wire Cutting | Motsoako oa aluminium | A6061,A5052,2A17075 , joalo-joalo. | Ho roala | Sekoti se entsoeng ka galvanized, Gold Plating, Nickel Plating, Chrome Plating, Zinc nickel alloy, Titanium Plating, Ion Plating |

| Ts'epe e sa beng le mabali | SUS303,SUS304,SUS316,SUS316L,SUS420,SUS430,SUS301, joalo-joalo. | Anodized | Oxidation e thata, e Hlakileng ea Anodized, ea Anodized ea Mmala | |

| Tšepe ea carbon | 20#,45#, joalo-joalo. | Ho roala | Ho roala ha hydrophilic,Ho roala ka Hydrophobic,Ho roala ka vacuum,Taemane Joaloka Carbon(DLC),PVD (Golden TiN; Black:TiC, Silver:CrN) | |

| Tšepe ea tungsten | YG3X,YG6,YG8,YG15,YG20C,YG25C | |||

| Lintho tse entsoeng ka polymer | PVDF,PP,PVC,PTFE,PFA,FEP,ETFE,EFEP,CPT,PCTFE,PEKE | Ho benya | Ho bentša ka mochini, ho bentša ka electrolytic, ho bentša ka lik'hemik'hale le ho bentša nano | |

Bokhoni ba ho sebetsa

| Thekenoloji | Lenane la Mechini | Tshebeletso |

| CNC Milling | Mechining ea li-axis tse hlano | Sebaka sa Tšebeletso: Prototype & Mass Production |

Lipotso Tse Botsoang Hangata

1.Potso: Ke mefuta efe ea likarolo tseo u ka li sebetsanang?

Karabo: Re ka sebetsana le mefuta e fapaneng ea likarolo tse entsoeng ka thepa e kang tšepe, polasetiki le letsopa.Re latela ka tieo litšoantšo tsa moralo tse fanoeng ke moreki ho etsa machining ho latela litlhoko tsa bona.

2.Potso: Nako ea hau ea tlhahiso ea tlhahiso ke efe?

Karabo: Nako ea tlhahiso ea rona e tla itšetleha ka ho rarahana, bongata, thepa le litlhoko tsa bareki ba likarolo.Ka tloaelo, re ka qeta tlhahiso ea likarolo tse tloaelehileng ka matsatsi a 5-15 ka potlako.Bakeng sa mesebetsi e potlakileng le lihlahisoa tse nang le bothata ba ho sebetsa ka thata, re ka leka ho khutsufatsa nako ea ho tsamaisa thepa.

3.Potso: Na likarolo li lumellana le litekanyetso tse nepahetseng?

Karabo: Re nka mehato e tiileng ea ho laola boleng le litekanyetso tsa tlhahlobo nakong ea ts'ebetso ea tlhahiso ho netefatsa boleng.

4.Potso: Na u fana ka litšebeletso tsa tlhahiso ea mohlala?

Karabo: E, re fana ka litšebeletso tsa tlhahiso ea mohlala.Bareki ba ka re fa litšoantšo tsa meralo le litlhoko tsa lisampole, 'me re tla etsa tlhahiso le ho e lokisa, le ho etsa liteko le tlhahlobo ho netefatsa hore lisampole li fihlela litlhoko le maemo a bareki.

5.Potso: Na u na le bokhoni ba ho iketsetsa mochini?

Karabo: E, re na le lisebelisoa tse fapaneng tse tsoetseng pele tsa mochini oa mochini, tse ka ntlafatsang katleho ea tlhahiso le ho nepahala.Re lula re ntlafatsa le ho ntlafatsa lisebelisoa le theknoloji ho fihlela litlhoko tsa bareki.

6.Potso: U fana ka litšebeletso life ka mor'a thekiso?

Karabo: Re fana ka lits'ebeletso tse felletseng ka mor'a thekiso, ho kenyeletsoa ho kenya sehlahisoa, ho laela, ho lokisa le ho lokisa, joalo-joalo Re boetse re fana ka tšehetso ea tekheniki le tataiso ho netefatsa hore bareki ba fumana boiphihlelo bo botle ba mosebelisi le boleng ba sehlahisoa.