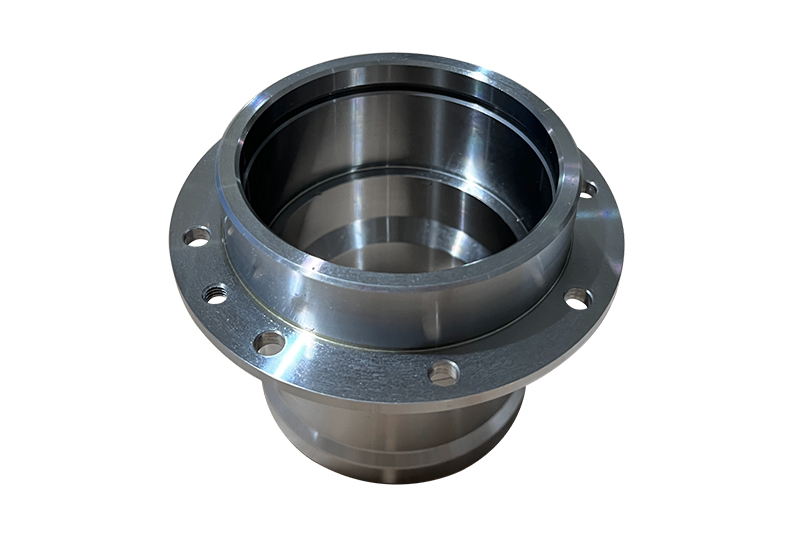

Lager flansch/bearing flange/Robotics precision part

Tsanangudzo

Robhoti inotakura flange chinhu chakanyatsogadzirirwa kutsigira uye kutakura mutoro werobhoti ruoko.Kazhinji inogadzirwa nesimbi, ine chimiro chedenderedzwa uye gomba repakati, uye inoshandiswa kubatanidza ruoko rwerobhoti kune zvimwe zvikamu zvemarobhoti.Iyo inotakura flange inofanirwa kunge iine chaiyo chaiyo geometric chimiro uye zviyero kuti ive nechokwadi chechokwadi uye kugadzikana kwerobhoti.Inofanirawo kukwanisa kumira nehuremu uye torque yerobhoti kuti ive nechokwadi chekufamba uye kwakaringana marobhoti.Naizvozvo, kugadzira marobhoti ane flange inyanzvi yakaoma uye inodiwa-inoda maitiro.

Application

Robhoti inotakura maflange zvinhu zvakakosha mumarobhoti masisitimu, anowanzo shandiswa kutsigira uye kutakura ruoko rwerobhoti uye kubatanidza zvimwe zvinhu zvemarobhoti.Chishandiso chayo chakakura kwazvo, kusanganisira asi chisina kuganhurirwa kune anotevera minda:

Industrial Automation:Robhoti inotakura flange inogona kushandiswa munzvimbo dzakasiyana siyana dzemaindasitiri, sekugadzira mota, kugadzira zvigadzirwa zvemagetsi, uye kugadzira chikafu, nezvimwe.

Nezveutano:Marobhoti ari kuwedzera kushandiswa munharaunda yehutano, semabhobhoti ekuvhiya, marobhoti ekugadzirisa, etc. Robhoti inotakura flange inoita basa rinokosha mumarobhoti aya.

Military Applications:Robhoti inotakura maflange inogona zvakare kushandiswa mune zvechiuto zvikumbiro, senge mauto marobhoti, drones, nezvimwe.

Tsika Kugadziridza Yepamusoro-chaiyo Machining Zvikamu

| Machinery Process | Materials Option | Finish Option | ||

| CNC Milling CNC Turning CNC Kukuya Precision Wire Cutting | Aluminium alloy | A6061,A5052,2A17075 , nezvimwewo. | Plating | Galvanized, Gold Plating, Nickel Plating, Chrome Plating, Zinc nickel alloy, Titanium Plating,Ion Plating |

| Simbi isina ngura | SUS303,SUS304,SUS316,SUS316L,SUS420,SUS430,SUS301 nezvimwe. | Anodized | Yakaoma oxidation, Yakajeka Anodized, Ruvara Anodized | |

| Carbon steel | 20#,45# nezvimwewo. | Coating | Hydrophilic coating,Hydrophobic coating,Vacuum coating,Diamondi Sekabhoni(DLC),PVD (Golden TiN; Dema:TiC, Silver:CrN) | |

| Tungsten simbi | YG3X,YG6,YG8,YG15,YG20C,YG25C | |||

| Polymer zvinhu | PVDF,PP,PVC,PTFE,PFA,FEP,ETFE,EFEP,CPT,PCTFE,PEEK | Kupukuta | Mechanical polishing, electrolytic polishing, chemical polishing uye nano polishing | |

Processing Capacity

| Vadivelu Comedy Technology | Machine List | Service |

| CNC Milling | Mashanu-axis Machining | Service Scope:Prototype & Mass Production |

Mibvunzo Inowanzo bvunzwa

1.Mubvunzo: Ndeapi marudzi ezvikamu zvaunogona kugadzirisa?

Mhinduro: Tinogona kugadzirisa marudzi akasiyana ezvikamu zvakagadzirwa nezvinhu zvakaita sesimbi, plastiki, uye ceramics.Isu tinonyatso kutevedzera dhizaini yedhizaini yakapihwa nemutengi kuita machining zvinoenderana nezvavanoda.

2.Mubvunzo: Ndeipi nguva yako yekugadzira yekufambisa?

Mhinduro: Nguva yedu yekutungamira yekugadzira ichaenderana nekuoma, huwandu, zvinhu, uye zvinodiwa nevatengi zvezvikamu.Kazhinji, tinogona kupedzisa kugadzirwa kwezvikamu zvakajairika mumazuva 5-15 nekukurumidza.Kune mabasa ekukurumidzira uye zvigadzirwa zvine yakaoma machining kuomerwa, isu tinogona kuedza kupfupisa yekuendesa nguva yekutungamira.

3.Mubvunzo: Zvikamu zvinowirirana nemitemo yakakodzera here?

Mhinduro: Isu tinotora matanho akasimba ekudzora emhando uye zviyero zvekuongorora panguva yekugadzira maitiro kuti tive nechokwadi chemhando.

4.Mubvunzo: Iwe unopa semuenzaniso wekugadzira masevhisi?

Mhinduro: Hongu, isu tinopa sampuli yekugadzira masevhisi.Vatengi vanogona kutipa dhizaini yedhizaini uye sampuli zvinodiwa, uye isu tichaita kugadzira nekugadzirisa, uye kuita bvunzo nekuongorora kuti tive nechokwadi chekuti samples dzinosangana nezvinodiwa nevatengi uye zviyero.

5.Mubvunzo: Une otomatiki machining kugona?

Mhinduro: Ehe, isu tine akasiyana epamberi otomatiki machining midziyo, iyo inogona kuvandudza kugadzirwa kwehunyanzvi uye kunyatsoita.Isu tinogara tichivandudza nekusimudzira michina uye tekinoroji kuti isangane nezvinodiwa nevatengi.

6.Mubvunzo: Ndeapi mushure mekutengesa masevhisi aunopa?

Mhinduro: Tinopa masevhisi akazara mushure mekutengesa, kusanganisira kuiswa kwechigadzirwa, kutumira, kugadzirisa, nekugadzirisa, nezvimwewo. Isu tinopawo rubatsiro rwehunyanzvi uye kutungamira kuti tive nechokwadi chekuti vatengi vanowana ruzivo rwemushandisi rwakanyanya uye kukosha kwechigadzirwa.