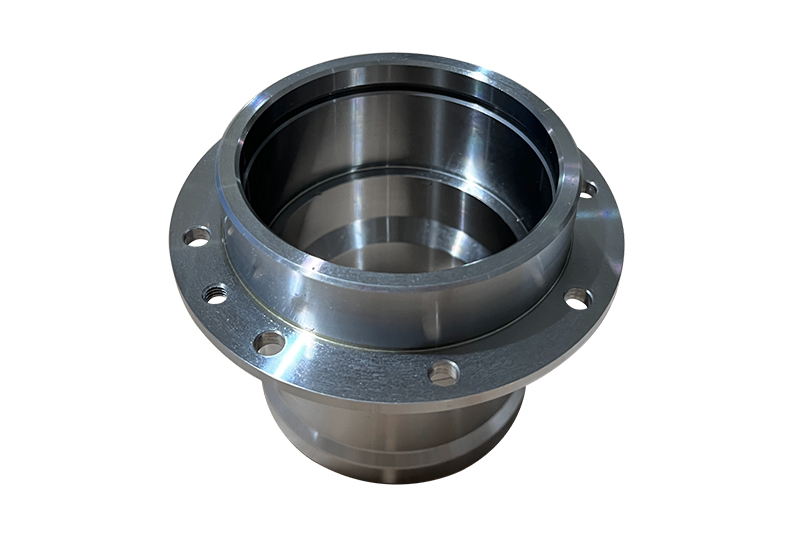

Lager flansch / bearing flange / Robotics precision qhov

Kev piav qhia

Ib tug neeg hlau bearing flange yog ib feem tshwj xeeb tsim los pab txhawb thiab ris lub nra ntawm ib tug neeg hlau caj npab.Nws feem ntau yog ua los ntawm cov khoom siv hlau, muaj ib lub voj voog thiab lub hauv paus qhov, thiab yog siv los txuas cov neeg hlau caj npab mus rau lwm cov khoom siv neeg hlau.Cov kabmob flange yuav tsum muaj cov duab geometric zoo thiab qhov ntev kom ntseeg tau qhov tseeb thiab ruaj khov ntawm tus neeg hlau.Nws tseem yuav tsum muaj peev xwm tiv taus qhov hnyav thiab lub zog ntawm tus neeg hlau kom ntseeg tau tias tus neeg hlau txav tau yooj yim thiab meej.Yog li ntawd, kev tsim cov neeg hlau bearing flanges yog cov txheej txheem technically complex thiab precision-thov txheej txheem.

Daim ntawv thov

Robotic bearing flanges yog cov khoom tseem ceeb hauv cov tshuab neeg hlau, feem ntau yog siv los txhawb thiab nqa cov neeg hlau caj npab thiab txuas lwm cov khoom siv neeg hlau.Nws daim ntawv thov yog qhov dav heev, suav nrog tab sis tsis txwv rau cov haujlwm hauv qab no:

Industrial Automation:Robotic bearing flanges tuaj yeem siv rau ntau yam kev lag luam automation scenarios, xws li kev tsim tsheb, kev tsim khoom siv hluav taws xob, thiab kev ua zaub mov, thiab lwm yam.

Kev kho mob:Cov neeg hlau tau siv ntau dua hauv kev kho mob, xws li phais neeg hlau, kho neeg hlau kho mob, thiab lwm yam. Robotic bearing flanges ua lub luag haujlwm tseem ceeb hauv cov neeg hlau no.

Kev siv tub rog:Robotic bearing flanges kuj tseem siv tau rau hauv kev siv tub rog, xws li tub rog robots, drones, thiab lwm yam.

Kev cai ua ntawm High-precision Machining Parts

| Tshuab txheej txheem | Khoom siv xaiv | Finish Option | ||

| CNC Milling tshuab CNC tig CNC sib tsoo Precision Hlau Txiav | Aluminium alloy | A6061,A5052,2a17075 ,ua. | Plating | Galvanized, Kub Plating, Nickel Plating, Chrome Plating, Zinc Nickel Alloy, Titanium Plating, Ion Plating |

| Stainless hlau | SUS 303,SUS 304,SUS 316,SUS 316L,SUS 420,SUS 430,SUS301, thiab lwm yam. | Anodized | Hard oxidation, Clear Anodized, Xim Anodized | |

| Cov pa roj carbon steel | 20#,45 #, thiab lwm yam. | Txheej | Hydrophilic txheej,Hydrophobic txheej,Nqus txheej,Pob zeb diamond zoo li Carbon(DLC),PVD (Golden TiN; Dub: TiC, Nyiaj: CrN) | |

| tungsten hlau | YG3X,YG6,YG8,YG15,YG20C,YG25C | |||

| Cov khoom siv polymer | PVDF,PP,PVC,PTFE,PFA,FEP,ETFE,EFEP,CPT,PCTFE,PEB | Polishing | Mechanical polishing, electrolytic polishing, tshuaj polishing thiab nano polishing | |

Kev Ua Tau Zoo

| Technology | Tshuab List | Kev pabcuam |

| CNC Milling tshuab | Tsib-axis Machining | Kev Pabcuam Scope: Prototype & Mass Production |

Cov lus nug nquag

1.Cov lus nug: Yam khoom twg koj tuaj yeem ua tau?

Teb: Peb tuaj yeem ua ntau hom khoom ua los ntawm cov ntaub ntawv xws li hlau, yas, thiab ceramics.Peb nruj me ntsis ua raws li tus qauv kos duab muab los ntawm cov neeg siv khoom los ua machining raws li lawv cov kev xav tau.

2.Ntiaj teb: Koj lub sijhawm ua khoom lag luam yog dab tsi?

Teb: Peb lub sij hawm ua cov khoom siv lead ua yuav nyob ntawm qhov nyuaj, ntau, cov khoom siv, thiab cov neeg siv khoom xav tau ntawm cov khoom.Feem ntau, peb tuaj yeem ua tiav cov khoom lag luam zoo tib yam hauv 5-15 hnub ntawm qhov ceev tshaj plaws.Rau cov hauj lwm ceev thiab cov khoom uas nyuaj machining nyuaj, peb tuaj yeem sim ua kom luv lub sij hawm xa tuaj.

3.Nrhiav: Cov khoom puas ua raws li cov qauv tsim?

Teb: Peb tau txais kev tswj xyuas nruj thiab cov qauv tshuaj xyuas thaum lub sijhawm tsim khoom los xyuas kom meej qhov zoo.

4.Nrhiav: Koj puas muab cov qauv tsim khoom?

Teb: Yog, peb muab cov kev pab cuam ntau lawm.Cov neeg siv khoom tuaj yeem muab peb cov qauv tsim thiab cov qauv yuav tsum tau ua, thiab peb yuav ua cov khoom tsim thiab kev ua haujlwm, thiab ua kev sim thiab tshuaj xyuas kom ntseeg tau tias cov qauv ua tau raws li cov neeg siv khoom xav tau thiab cov qauv.

5.Ntiaj teb: Koj puas muaj peev xwm ua haujlwm machining?

Teb: Yog, peb muaj ntau yam khoom siv tshuab ua haujlwm siab heev, uas tuaj yeem txhim kho kev tsim khoom thiab raug.Peb niaj hnub hloov kho thiab txhim kho cov cuab yeej siv thiab thev naus laus zis kom tau raws li qhov xav tau ntawm cov neeg siv khoom.

6.Cov lus nug: Koj puas muab kev pabcuam tomqab muag?

Teb: Peb muab cov kev pab cuam tom qab muag tag, nrog rau cov khoom siv installation, commissioning, txij nkawm, thiab kho, thiab lwm yam. Peb kuj muab kev pab txhawb nqa thiab kev taw qhia kom ntseeg tau tias cov neeg siv khoom tau txais txiaj ntsig zoo tshaj plaws ntawm cov neeg siv khoom thiab cov khoom muaj nqis.