Lager flansch/haɓaka flange/Robotics daidai sashi

Bayani

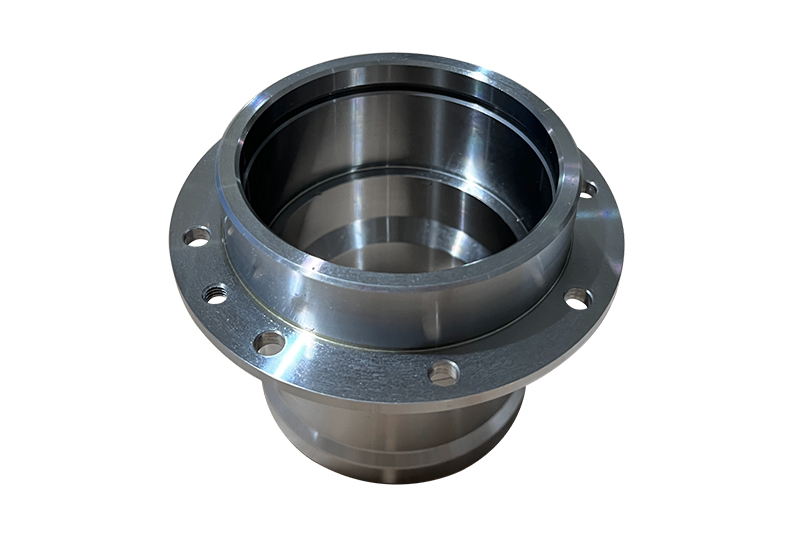

Flange mai ɗaukar mutum-mutumi abu ne da aka kera musamman don tallafawa da ɗaukar nauyin hannun mutum-mutumi.Yawanci ana yin shi da kayan ƙarfe, yana da siffar madauwari da rami na tsakiya, kuma ana amfani da shi don haɗa hannun mutum-mutumi da sauran kayan aikin mutum-mutumi.Flange mai ɗaukar nauyi dole ne ya kasance yana da madaidaicin siffar geometric da girma don tabbatar da daidaito da kwanciyar hankali na mutum-mutumi.Hakanan dole ne ya iya jure nauyi da karfin robobin don tabbatar da motsin mutum-mutumi da santsi.Don haka, masana'anta masu ɗaukar flanges na mutum-mutumi tsari ne mai rikitarwa na fasaha da madaidaicin tsari.

Aikace-aikace

Flanges masu ɗaukar mutum-mutumi sune mahimman abubuwan da ke cikin tsarin mutum-mutumi, galibi ana amfani da su don tallafawa da ɗaukar hannun mutum-mutumi da haɗa sauran abubuwan haɗin robot.Aikace-aikacen sa yana da faɗi sosai, gami da amma ba'a iyakance ga fage masu zuwa ba:

Kayan Automatin Masana'antu:Za a iya amfani da flanges masu ɗauke da robotic a cikin yanayin yanayin sarrafa kansa na masana'antu daban-daban, kamar kera motoci, kera samfuran lantarki, sarrafa abinci, da sauransu.

Kiwon Lafiya:Ana ƙara amfani da robobin a fagen kiwon lafiya, kamar mutum-mutumin tiyata, mutum-mutumi na gyarawa, da dai sauransu. Flanges masu ɗauke da na'ura suna taka muhimmiyar rawa a cikin waɗannan mutummutumin.

Aikace-aikacen soja:Hakanan za'a iya amfani da flanges na robotic a aikace-aikacen soja, kamar mutummutumi na soja, jirage marasa matuƙa, da sauransu.

Ƙirƙirar Ƙwararren Ƙwararren Ƙwararren Machining

| Tsarin Injiniya | Zabin Kayayyaki | Zaɓin Ƙarshe | ||

| CNC Milling Canjin CNC Farashin CNC Daidaitaccen Yankan Waya | Aluminum gami | A6061,A5052,2A17075, da dai sauransu. | Plating | Galvanized, Plating Zinariya, Plating Nickel, Chrome Plating, Zinc nickel gami, Titanium Plating, Ion Plating |

| Bakin karfe | SUS303,SUS304,SUS316,Saukewa: SUS316L,SUS420,SUS430,SUS301, da dai sauransu. | Anodized | Hard hadawan abu da iskar shaka, Clear Anodized, Launi Anodized | |

| Karfe Karfe | 20#,45#, da sauransu. | Tufafi | Hydrophilic shafi,Hydrophobic shafi,Vacuum shafi,Diamond Kamar Carbon(DLC),PVD (Golden TiN; Black: TiC, Azurfa: CrN) | |

| Tungsten karfe | YG3X, YG6, YG8, YG15, YG20C, YG25C | |||

| Kayan polymer | PVDF,PP,PVC,PTFE,PFA,FEP,ETFE,EFEP,Farashin CPT,PCTFE,KYAUTA | goge baki | Gyaran injina, gogewar lantarki, gogewar sinadarai da gogewar nano | |

Ƙarfin sarrafawa

| Fasaha | Jerin Injin | Sabis |

| CNC Milling | Machining na axis biyar | Iyakar Sabis: Samfura & Samar da Jama'a |

Tambayoyin da ake yawan yi

1.Tambaya: Wadanne nau'ikan sassa za ku iya aiwatarwa?

Amsa: Za mu iya sarrafa nau'ikan sassa daban-daban da aka yi da kayan kamar karfe, filastik, da yumbu.Muna bin zane-zanen ƙira da abokin ciniki ya bayar don yin mashin ɗin bisa ga buƙatun su.

2.Tambaya: Menene lokacin jagoran ku na samarwa?

Amsa: Lokacin jagoranmu na samarwa zai dogara ne akan rikitarwa, yawa, abu, da buƙatun abokin ciniki na sassan.Yawanci, za mu iya kammala samar da talakawa sassa a cikin 5-15 kwanaki a cikin sauri.Don ayyuka na gaggawa da samfurori tare da ƙayyadaddun wahalar inji, za mu iya ƙoƙarin rage lokacin jagoran bayarwa.

3.Tambaya: Shin sassan sun cika ka'idodin da suka dace?

Amsa: Muna ɗaukar tsauraran matakan kula da ingancin inganci da ka'idodin dubawa yayin aikin samarwa don tabbatar da ingancin.

4.Question: Kuna bayar da sabis na samar da samfurin?

Amsa: Ee, muna ba da sabis na samar da samfur.Abokan ciniki za su iya samar mana da zane-zanen zane da buƙatun samfurin, kuma za mu aiwatar da samarwa da sarrafawa, da gudanar da gwaji da dubawa don tabbatar da cewa samfuran sun cika buƙatun abokin ciniki da ka'idoji.

5.Tambaya: Kuna da ikon sarrafa kayan aiki ta atomatik?

Amsa: Ee, muna da kayan aikin injina na ci gaba daban-daban, waɗanda zasu iya haɓaka ingantaccen samarwa da daidaito.Kullum muna sabuntawa da haɓaka kayan aiki da fasaha don saduwa da bukatun abokan ciniki.

6.Tambaya: Menene sabis na tallace-tallace da kuke bayarwa?

Amsa: Muna ba da cikakken sabis na tallace-tallace, ciki har da shigarwa na samfur, ƙaddamarwa, kulawa, da gyarawa, da dai sauransu. Har ila yau, muna ba da goyon bayan fasaha da jagoranci don tabbatar da cewa abokan ciniki sun sami mafi kyawun ƙwarewar mai amfani da ƙimar samfurin.